- Position:

- Batte Melt pump > NEWS >

Compare gear pumps and centrifugal pumps

1, with the speed and efficiency of the centrifugal pump best efficiency point (BEP) and change, a model of the pump best efficiency point in the form of a specific flow rate and pressure exists. However, if the flow rate changes, the efficiency of the gear pump is almost constant. Gear pump out is a smooth non-pulsating flow.

2, for any liquid, the flow rate of the centrifugal pump with pressure changes are; gear pump on the contrary, regardless of how changes in the outlet pressure, the flow rate is constant. So, if the system has a different outlet pressure, you can consider using a gear pump.

3, when the viscosity increases, the centrifugal pump efficiency starts to decrease and increase the power consumption; gear pump under the conditions of high viscosity can maintain high efficiency. The smaller the working power (operating) cost reduction.

4, the centrifugal force needs to start, and the gear pump is self-priming pump, and less commonly required NPSH.

Gear pumps and other positive displacement pumps Comparison of the ring

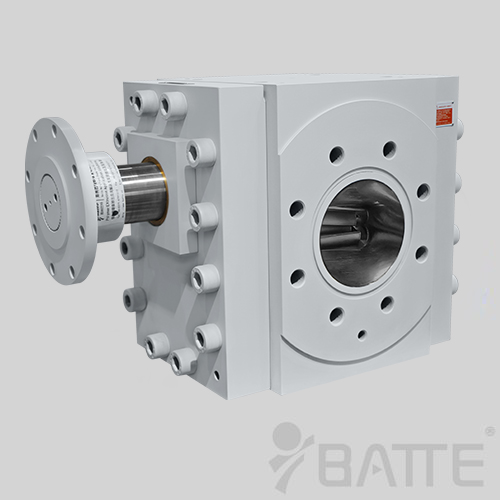

Comparison of external engagement with the melt gear pump

1, there are four external gear pump bushing in contact with the fluid. If the fluid contains particles bushing, in contact therewith, the more the higher the frequency of replacement of the bushing means.

2, two external gear pump teeth are worn, but only wear the gear pump gear side. Internal gear pump can be adjusted through the thrust bearing end play, to compensate for wear.

3, external gear pump can not handle solids, while internal gear pump has been successfully applied abrasive applications.

4, with the internal gear pump (1450/1750 rpm) compared to external gear pumps run faster (2850/3450rpm).

Compare cam pumps and internal gear pumps

1, there are two cam pump stuffing, this means there are two seals; while internal gear pump only needs a seal. As we all know, the less sealed, maintenance more convenient maintenance.

2, the cam drive gear pumps need to be synchronized, maintenance and set very strict requirements; internal gear pump drive gear is not synchronized, easy to maintain.

3, lobe pumps are usually only made ??of stainless steel, while the internal gear pump can be used to manufacture a variety of materials including stainless steel, the user can choose according to application requirements.

4, cam pump in situ and in-situ cleaning disinfection, and internal gear pump can not be achieved.

Comparison screw with internal gear pump

1, the stator of the screw pump is made ??of synthetic rubber, require frequent replacement, high maintenance costs. The ring gear and the gear pump are made ??of a metal, a longer service life.

2, the screw does not work at very high temperatures. The internal gear pump can operate at temperatures up to 300 ℃ conditions.

3, compared with the ring gear pump, screw pump can handle larger solid particles, and can be operated at higher pressures.

Any questions about our products, please feel free to contact us! We promise you high-end products and first-class service.Look forward to our cooperation!!!

- sales@battemachinery.com

- +0086-371-67991755