- Position:

- Batte Melt pump > PRODUCT > Other Types of Melt Pump >

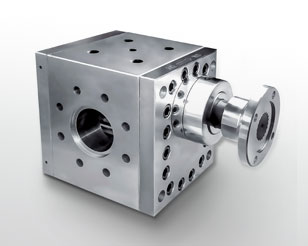

Metering pumps for plastic industry is used for improving the product quality. Melt gear pumps are mainly used for transportation, pressurization and metering of high temperature or high viscosity plastic industry.

One Whole Set of Metering pumps for plastic industry System Comprise :

1. Melt Pump

2. Driven Motor System: motor + reducer

3. Control System: PLC touchscreen system

The Performance Advantage of Batte Melt Pump Model:

1. Stabilizing outlet pressure;

2. Improving the products quality;

3. Increasing the extrusion output;

4. Reducing unit energy consumption;

5. Prolonging the service time of extruder

The Installation of Metering pumps for plastic industry

Installation Method: Motor+Reducer+Universal Coupling+Melt Pump

Installation Method: Motor+reducer+universal coupling+melt pump

You can use control or direct current governor for the motor, and can adjust the flow to your demands optionally. We suggest using servo motor for speed governing if you demand high precision.

- Place of Origin: Henan, China (Mainland)

- Brand Name: BATTE

- Theory: External Meshed Positive Displacement Gear Pump

- Structure: Gear Pump

- Usage: Polymer Melt Gear Pump

- Power: Electric

- Standard or Nonstandard: Standard

- Fuel: No Need

- Pressure: High Pressure

- Application: ttransportation, pressurization or metering of polymer melt

- Scope of Application: Almost all kinds of polymers

- Viscosity:Up to 40000Pas

- Material for Pump Housing: M4 Steel

- Gear Tooth:Straight (Optional)

- Melt Pump Model:0.1CC-6000CC

- Capacity Delivery:0.05-120000L/H

- Max. Outlet Pressure: Less than 40MPa

- Max. Differential Pressure: 275Bar

- Heating Method:Stainless Steel Heating Rod

- Sealing Method:Mechanical Sealing (Optional)

| Packaging Details: | Items are packed in wooden cases. |

|---|---|

| Delivery Detail: | 5-6 Weeks |