- Position:

- Batte Melt pump > NEWS >

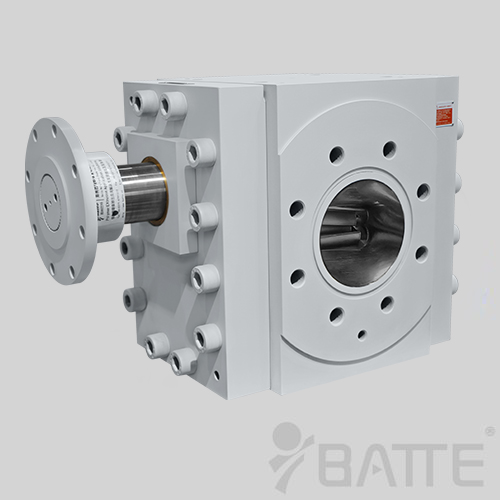

Machine malfunction of Screw extruder barrel

Quality of work the screw and barrel combination of these two parts of the plasticized material, product quality and production efficiency, and have a significant impact. Their work quality and accuracy of the two parts of the manufacturing, assembly space related. When twenty badly worn extruder production drops, they should arrange for the screw, barrel repairs.

First, the damage causes the screw and barrel

A screw in the barrel rotates, the material and the friction between the two, so that the work surface is gradually screw and barrel wear: screw diameter is gradually reduced, the inner diameter of the barrel is gradually increased. Thus, the gap with the diameter of the screw and barrel, with the gradual wear and tear and a little bit of both increased. However, due to the resistance in front of the cylinder head and manifold does not change, which increases the material to be extruded move forward leakage flow, i.e., material from the diameter of the feed gap at the direction of the flow amount. Resulting in decreased production of extruder. This phenomenon has also caused material increases the residence time in the barrel, causing the material to decompose. If polyethylene, hydrogen chloride gas generated by the decomposition of enhanced corrosion of the screw and barrel.

2, the material in any calcium carbonate filler and glass fiber, etc., can speed up the screw and barrel wear.

3, due to the plasticizing material is not uniform, or a metallic contaminant compound, so that a sudden increase in screw rotation torque, the torque exceeds the ultimate strength of the screw, the screw is broken. This is an unconventional accident damage.

Two screw fixes

1, broken screw according to the actual internal diameter of the barrel to consider, according to the normal clearance barrel outside diameter of the screw gives new manufacturing deviations.

2, reduced diameter threaded screw wear surface after treatment, thermal spraying wear-resistant alloy, and then by grinding to size. This method is generally a professional spray processing plant repair, the cost is still relatively low.

Any questions about our products, please feel free to contact us! We promise you high-end products and first-class service.Look forward to our cooperation!!!

- sales@battemachinery.com

- +0086-371-67991755