- Position:

- Batte Melt pump > NEWS >

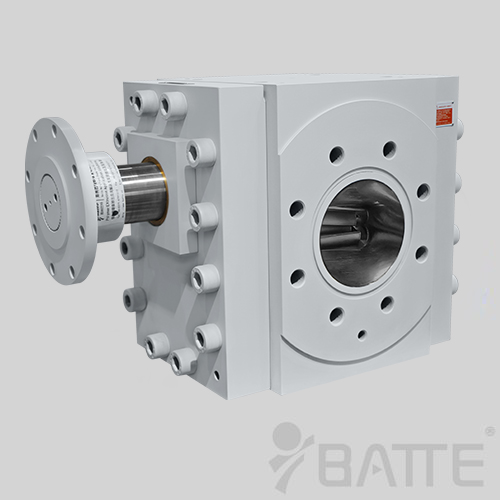

Development of melt gear pump booster plastic products industry

Fine customary high precision extrusion skills needed fine melt pump for extrusion can dispense subsequent processing techniques, the use of very well satisfied with the finished product needs to reach the decline along with information costs, improve product quality intentions. Today, the satisfaction of fine plastic products direct extrusion needs, a variety of sophisticated skills are now facing the market, the polymer melt during gear pump that is an important way. This skill is now widely used in chemical fiber, film, profiles, tubes, plates, cable, composite extrusion, granulation production line.

Beijing University of Chemical Rubber Machinery Research Institute through years of melt gear pump system has been successful end of the plastic melt gear pump series development and research and development, is now able to plan the production of goods such as plastic melt gear pump 28/28 (in pitch / tooth width), 56/56, 70/70, 90/90, etc., up to the maximum pressure differential entrances 30MPa, satisfaction is not the same need to be able to value and have been used in practice, made an outstanding role. Rubber Machinery Research Institute, Beijing University of Chemical body through a gear pump extruder in-depth research, planning and development of the 115 Compact gear pump extruder.

Gear pump for rubber molding same fine career boost. To the satisfaction of domestic needs for rubber melt gear pump, extruder gear pump. This unit has operating characteristics ambition to ensure that the amount of gear pump extrusion speed linear relationship can be completed on the value of accurate control, precision progressive scale commodity.

Skills to carry out sophisticated multilayer coextrusion

Data and other information complex multi-layer composite packaging with high skills to use the function of isolation, cut off from the information summarized and sale of high-barrier function or other special mechanical, thermal, and other data, the need to complete a specific function. Co-extruded composite film structure plan gradually need to be able to reach the set functions, skills, capital, environmental protection, security system, the secondary processing in the realm of one's ambitions, and then complete the composite layers to maximize the likelihood of suppliers seeking to become One of skill. Guangdong Jinming Plastics Equipment Co., seven composite film coextrusion blow skills can be described as a typical Chinese conducted in this category.

The seven composite film coextrusion blow molding machine includes an optional key skills: one long and two short pitch screw plastics extrusion system changes, engineering analysis software to optimize the oscillation induced plasticizing equipment planning, graphic valve bonus die and inclined valves addition die, skills and dual outlet inside the cold vacuum cooling skills, multi-component metering feeder weight loss, online accurate film thickness control system, the computer will automatically set control system and bus control (CANOPEN) skills .

In one of the favorites along with the increase in the number of layers, the film used to produce special function skills are also carried out in the market. Guangdong Shi Cheng planning produced a width of PP environmental grainy film's casting production line 3150mm. The production line capacity beyond 800kg / h. Screw planning for the high-speed cutting, mixing, plasticizing screw high efficiency, customers can directly use the highly filled calcium carbonate powder and inorganic pigments toner, and then save the precious raw material costs. In addition to the entire line of environmentally friendly production of PP grainy film production, but also be able to produce other goods sensitive to transform and expand the customer commodity varieties. Shi Cheng trial production in the process, not only the output of the beautiful PP grainy film, also produced a CPP film, PP film and PP stationery stationery sheet.

Any questions about our products, please feel free to contact us! We promise you high-end products and first-class service.Look forward to our cooperation!!!

- sales@battemachinery.com

- +0086-371-67991755