- Position:

- Batte Melt pump > NEWS >

Application of melt spinning pump

Melt spinning pump is an important component of the chemical fiber spinning machine, also known as metering pumps. To control the flow supplied to the spinning solution or melt spinneret, thereby obtaining the resultant fiber fineness of control. Demand for small size and layout of the fine, and sometimes demand high temperatures. Generally made of stainless steel. There are two types of gear pumps and piston pumps, the former is more commonly used. Early use of axial piston pump spinning, spinning gear now have the choice pump.

Melt spinning pump in the country is still in the development stage of development, skill level of both performance and quality needs further improvement. It accurately measure polymer solution or melt evenly and transported to the spinning head.

Melt spinning pump that wet spinning and dry spinning pump. Such low temperatures using the pump, according to the nature of the spinning solution, corrosion-resistant and wear-resistant data production. Melt pump automatic gear clockwise to scroll, and the pump is wet spinning counterclockwise to scroll.

Spinning pump - Features

Compared with the common gear pump, spun small modulus gear pump operations, number of teeth; high precision, can reduce unevenness in flow rate; low operating speed of about 5 to 60 rev / min, the spinning fluid energy promptly filled teeth Valley. Spinning pump member having a dedicated high-definition specification on the spinning machine, the accuracy and uniformity of the fineness of the yarn in the fluid volume.

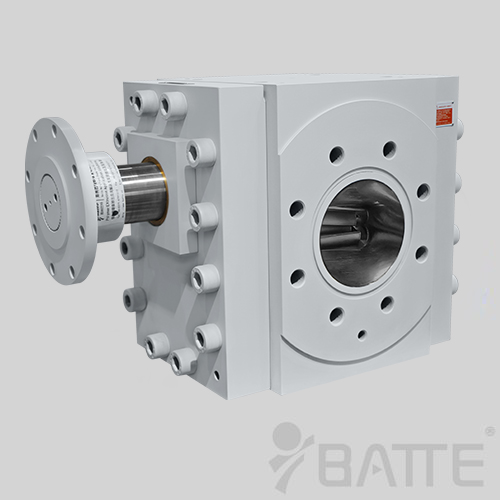

Spinning pump - constitute

A spinning pump comprising: a base plate, at least one tooth plate, a cover, a drive shaft, a spinning allow fluid flow inlet channel and a plurality of outlet channel, the corresponding channel of the pump housing and aligned with the channel, the fastening screws After a through hole through the cover and the tooth plate, the base plate convergence fitting and tighten the screw into the pump holder. A fitting groove, the depth of the spinning pump necessarily parallel to the bottom plate and the plane of the mating face of the touch melt at high pressure on the touch surface of the base plate and the engaging surface has excellent seal.

Based on the measurement of fluid transfer and spinning is not the same, spinning pump is divided into the following two categories:

① melt spinning pumps: for melt spinning, also known as heat pumps. Its main components are: the upper cover and lower cover, the intermediate plate (8 shaped plate) and a pair of hole-shaped work gear 8, two shaft and the coupling shaft. Spinning pump shaft through a coupling shaft femoral shaft automatically scroll through the key stock movements industry gears work, followed by rolling gear, the suction chamber melt spinning constantly filled teeth Valley and was taken to press out room.

When the teeth of two gears meshing with each other, the pressure of the chamber volume reduced, then included the melt pressure to the spinnerets. Such spinning pump operating temperature close to 300 ℃, when the temperature of the clean-up 450 ℃, so the data needs to be spinning pump is not deformed at high temperatures and has excellent wear resistance.

For diet needs long spinning melt-spun filaments, has developed a wide pump, the third gear pump and its spinning pump stack. Such pump strengths are: a spinning pump the equivalent of two, four, or more generally the spinning pump. Another kind of high-pressure pumps can be satisfied with the demand for spinning 300 to 500 kg / cm 2 when the high pressure spinning.

Any questions about our products, please feel free to contact us! We promise you high-end products and first-class service.Look forward to our cooperation!!!

- sales@battemachinery.com

- +0086-371-67991755