- Position:

- Batte Melt pump > NEWS >

Working principle of Hydraulic gear pump

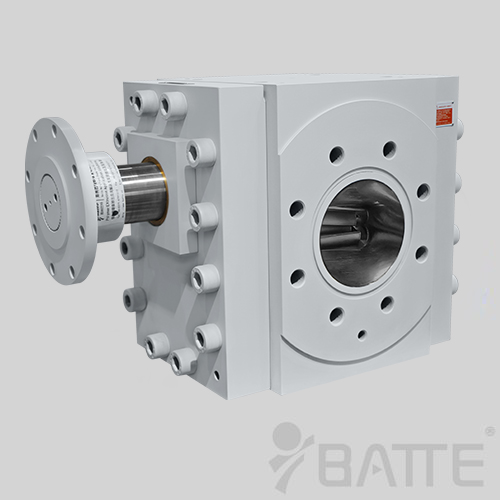

The concept is simple gear pump, i.e., its most basic form is the same in the two dimensions of the gear housing with a tight engagement with each other rotate, the interior of the housing similar to "8" shape, the two gears mounted on the inside , diameter and both sides of the housing gear tight fit. Material from the extruder at the inlet of two intermediate gears, and this space is filled with the rotation movement of the teeth along the shell, the final two hours from the toothing.

Speaking in terms, also called a positive displacement melt gear pump means, i.e. like a piston inside the cylinder when the fluid entering the space of one tooth of the other teeth, the liquid is squeezed mechanically discharged. Because the liquid is incompressible, the liquid and the teeth can not occupy the same space at the same time, so that the liquid was removed. Due to the continuous engagement of the teeth, this phenomenon occurs continuously and, therefore, at the outlet of the pump provides a continuous exclusion volume per revolution of the pump, the discharge amount is the same.

Continuous rotation of the drive shaft, the pump will discharge fluid continuously. Pump flow and speed of the pump directly. In fact, there is little loss in the amount of fluid in the pump, which makes the efficiency of the pump can not reach 100%, since these fluids are used to lubricate the bearings and gears on both sides, and the pump is not possible with no gap with the can not be discharged from the fluid outlet 100%, so a small amount of fluid loss is inevitable.

However, a good pump can be run out of material for the majority, still 93% to 98% efficiency. The viscosity or density changes in the process fluid, the pump will not be affected too much. If there is a damper, such as the discharge port side with a screen or a restrictor, the pump will push the fluid through them. If the damper changes in the work, that is, if the filter is dirty, blocked, or the back pressure of the limiter, the pump will maintain a constant flow rate, until the mechanical limits of the weakest parts of the device reaches (usually equipped with a torque limiter).

Any questions about our products, please feel free to contact us! We promise you high-end products and first-class service.Look forward to our cooperation!!!

- sales@battemachinery.com

- +0086-371-67991755