- Position:

- Batte Melt pump > NEWS >

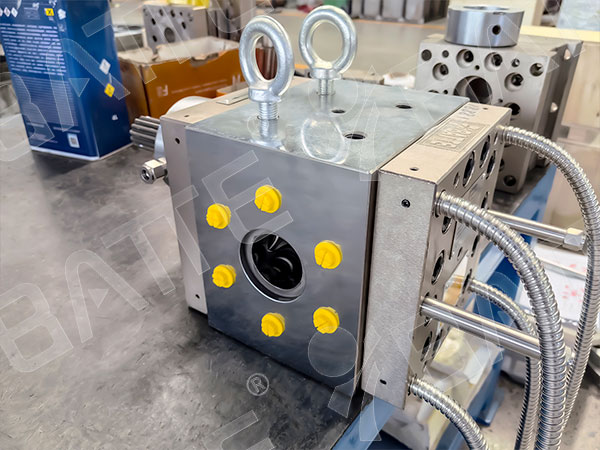

Plastic extrusion melt gear pump

Plastic extrusion melt pumps are critical equipment used in the plastic extrusion molding process for conveying, pressurizing, and metering high-temperature plastic melts.

Working Principle

A plastic extrusion melt pump is a positive displacement conveying device primarily composed of a pump housing, drive gear, and driven gear. The tooth profiles of the two gears, the pump body, and the side cover plates form the pump's feed zone, conveying zone, and discharge zone. When the gears rotate in the specified direction, the melt enters the gear tooth pockets in the feed zone. As the gears turn, the melt is drawn into the conveying zone from both sides. The gears re-engage, forcing the melt in the tooth pockets into the discharge zone, where it is pressurized and delivered to the outlet pipeline.

Structural Features

The melt pump structure resembles that of a gear pump in hydraulic systems, primarily consisting of a pump body, front and rear cover plates, two intermeshing gears, bearings, and seals. The gears are the core components. For conveying plastic melts, external gear pumps with involute straight or helical teeth are most commonly used. Operating under high-temperature, high-pressure, and high-viscosity conditions, the pump body is typically manufactured from alloy tool steel. The gears and shaft are integrated as a single unit and self-lubricate using the conveyed plastic melt.

Primary Functions

Pressure Boosting & Stabilization: Increases pressure of high-temperature plastic melt from the extruder, stabilizes melt pressure, effectively isolates pressure fluctuations in the feed zone, minimizes outlet pressure variations, and provides stable pressure to the extrusion die.

Precise Metering: Each revolution of the melt pump's gears delivers a constant displacement volume, enabling continuous and accurate melt metering to ensure stable melt flow rate.

Application Areas

Widely used in production lines for plastic films, sheets, plates, profiles, pipes, wires and cables, wire drawing, and co-extrusion. Capable of processing various polymer materials including PE, PC, PP, PVC, and more.

Email: sale@meltpump.com

WhatsApp: +86 158 3833 1071

Any questions about our products, please feel free to contact us! We promise you high-end products and first-class service.Look forward to our cooperation!!!

- sales@battemachinery.com

- +0086-371-67991755