- Position:

- Batte Melt pump > NEWS >

In which industries are melt gear pumps applied in industrial production?

Plastics and Resins Industry: Stable Extrusion, Enhanced Quality and Efficiency

Industry Challenges: During the extrusion molding of plastic pipes, sheets, films, and other products, pressure and flow fluctuations in the melt output from screw extruders lead to uneven product thickness, large dimensional tolerances, numerous surface defects, and high scrap rates.

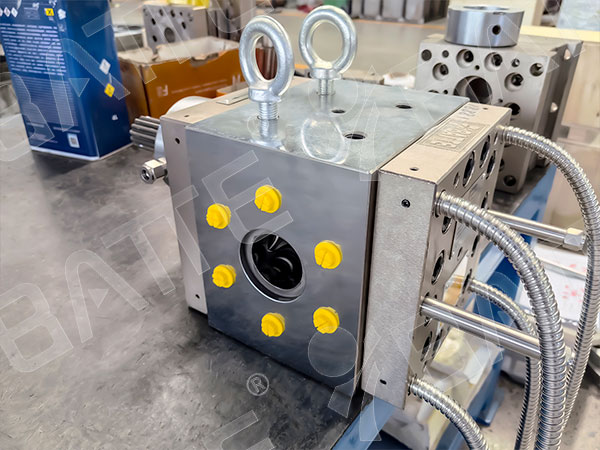

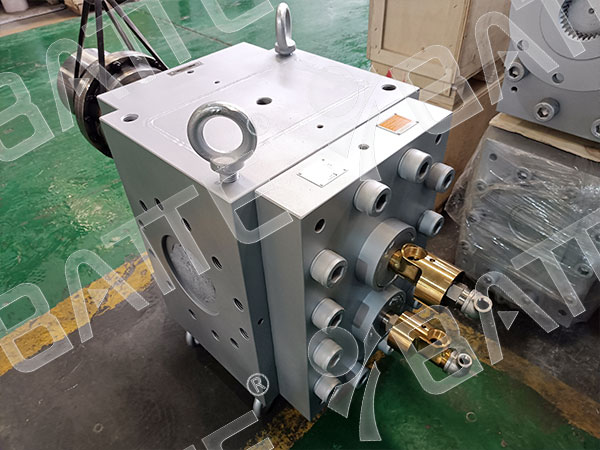

BATTE Melt Pump Solution: Installed between the extruder and die head, it functions as both a booster pump and metering pump. By eliminating screw fluctuations, it delivers absolutely stable pressure and linear flow to the die head. This significantly improves product dimensional accuracy, surface finish, and batch consistency while reducing extruder load for energy savings.

Rubber Processing Industry: Conquering High Viscosity, Optimizing Processes

Industry Challenge: Rubber compounds exhibit extremely high viscosity and poor flowability, causing feeding difficulties during mixing, calendering, or injection molding. This often leads to uneven plasticization and significant temperature fluctuations.

BATTE Melt Pump Solution: Serving as either a feed pump or booster pump, it delivers robust conveying power for high-viscosity rubber melts, ensuring stable and continuous material transfer to subsequent processes. This optimizes mixing and vulcanization, enhances uniformity in rubber product physical properties, and protects upstream equipment from impact.

Biodegradable Materials Industry (PLA/PBAT/PGA): Driving Green Production

Industry Challenges: PLA, PBAT, and other biodegradable materials exhibit poor thermal stability and narrow processing windows. They are highly sensitive to temperature, shear, and residence time during conveyance, making degradation prone to occur.

BATTE Melt Pump Solution: On polymerization and modification pelletizing lines, melt pumps enable gentle, stable, and pulsation-free conveying. They precisely control residence time in critical equipment, preventing localized overheating and degradation. This ensures high-quality, large-scale production of these environmentally friendly materials.

Coatings and Adhesives Industry: Precision Metering, Uniform Mixing

Industry Challenge: Producing high-end coatings, sealants, and hot-melt adhesives requires precise metering and efficient mixing of high-viscosity resins, fillers, and additives. Any formulation inaccuracy compromises product performance.

Melt Pump Solution: As a precision metering feed pump, it works in conjunction with static or dynamic mixers. It delivers base components of varying viscosities with precision and continuity, ensuring formula ratios are met with pinpoint accuracy. This results in a final product with stable performance and uniform mixing.

Despite vastly different application fields, melt gear pumps address core challenges across industries: conquering high viscosity, achieving stable flow rates, withstanding demanding conditions, and enhancing product quality. Their positive displacement principle ensures a linear relationship between flow rate and rotational speed, unaffected by minor fluctuations in pressure or viscosity. This makes them the “standard-equipment heart” for process industries pursuing stable, efficient, and precise production. Leveraging deep expertise across these industrial processes, Zhengzhou BATTE Machinery Co., Ltd. offers a comprehensive range of melt gear pumps and solutions—from 0.05 cc/r to 30,000 cc/r—for all operating conditions. We continuously empower customers to overcome material handling challenges and drive industrial advancement.

Email: sale@meltpump.com

WhatsApp: +86 158 3833 1071

Any questions about our products, please feel free to contact us! We promise you high-end products and first-class service.Look forward to our cooperation!!!

- sales@battemachinery.com

- +0086-371-67991755