- Position:

- Batte Melt pump > NEWS >

Melt pumps for sheet extrusion production lines

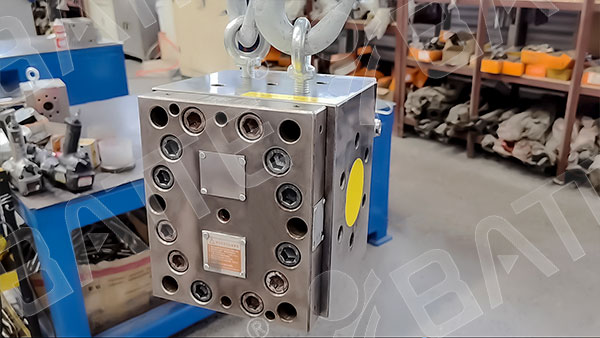

Melt pumps (melt gear pumps) play a central role in sheet extrusion production lines by stabilizing pressure and flow while enhancing plasticization quality. They are compatible with extrusion processes for various sheet materials including PP, PE, PET, PVC, and ABS, and are particularly suited for high-precision sheet production scenarios demanding wide widths and strict thickness tolerances.

Precise Flow and Pressure Stabilization

The extruder screw's conveying action exhibits periodic fluctuations. The melt pump utilizes the volumetric delivery characteristic of gear meshing to control extrusion pressure fluctuations within ±1%, eliminating transverse thickness variations and longitudinal streaks in the sheet. This stabilizes sheet thickness tolerances at ±2~5μm (depending on machine type and process). Simultaneously, it reduces fluctuations in extruder backpressure, minimizes uneven screw shear heat distribution, and prevents material degradation (e.g., thermal decomposition of PVC, hydrolysis of PET).

Enhanced Production Capacity and Energy Efficiency

The melt pump boosts the extruder's effective output efficiency by 10% to 30%. By ensuring stable melt delivery, it reduces scrap rates caused by pressure fluctuations. When paired with an extruder, it allows for lower screw speeds, minimizing mechanical wear and energy consumption while extending equipment lifespan.

Optimizing Melt Plasticization Quality

The melt pump's gentle and uniform shear action further mixes additives (e.g., color masterbatches, fillers) within the melt. This improves color consistency and mechanical property uniformity in sheet products, making it particularly suitable for sheet extrusion of highly filled (e.g., calcium carbonate-filled PP) and high-viscosity systems.

Typical Process Flow and Layout

Standard Process

Raw material drying → Extruder melting and plasticizing → Melt pump for pressure and flow stabilization → Melt filter (screen changer) → Static mixer → Sheet die head → Cooling and shaping rollers → Traction → Trimming → Winding

Layout Key Points

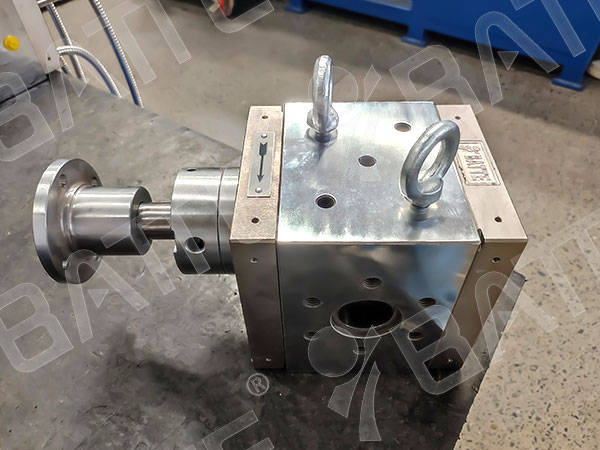

The melt pump must be coaxially installed with the extruder and die to minimize melt flow resistance;

A melt pressure sensor should be installed between the pump body and die to monitor pressure in real time and feed it back to the melt pump's variable frequency control system for closed-loop regulation;

For heat-sensitive materials (e.g., PVC, PET), the connecting piping between the melt pump and die should be minimized and insulated to reduce melt residence time.

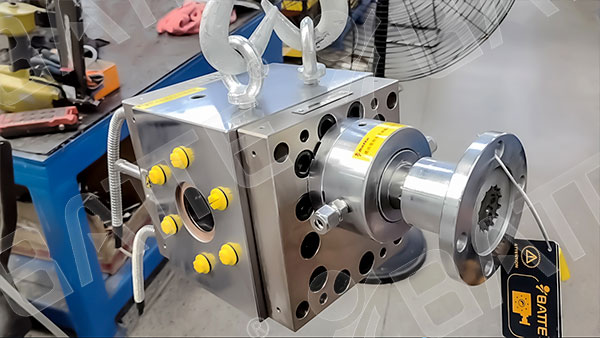

Supporting System Requirements

Temperature Control System: Independently regulate pump body and inlet/outlet pipe temperatures to prevent viscosity fluctuations caused by localized overheating or cooling.

Control System: Utilize PLC + touchscreen integrated control to achieve coordinated adjustment of melt pump speed, pressure, and temperature, supporting synchronized speed regulation with the extruder and take-up machine.

Filtration System: Must be equipped with an automatic screen changer featuring a filtration precision of ≥80–120 mesh to prevent impurities from entering the melt pump, causing wear, and ensuring sheet surface quality.

Email: sale@meltpump.com

WhatsApp: +86 158 3833 1071

Any questions about our products, please feel free to contact us! We promise you high-end products and first-class service.Look forward to our cooperation!!!

- sales@battemachinery.com

- +0086-371-67991755