- Position:

- Batte Melt pump > NEWS >

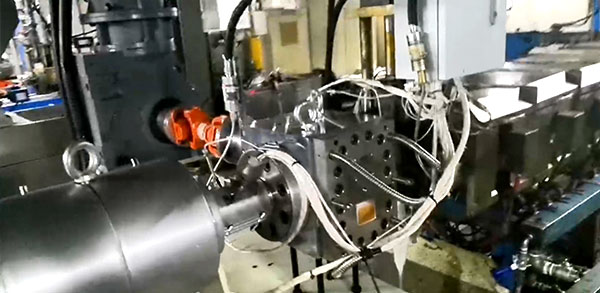

TPU extrusion melt pump and single plate screen changer

TPU extrusion melt pumps and screen changers are critical equipment in the TPU production process, performing the vital functions of pressurization, pressure stabilization, metering, and impurity filtration respectively.

Function: Typically installed between the extruder outlet and the die head, the TPU extrusion melt pump primarily pressurizes, stabilizes, and meters the TPU melt. This ensures stable and precise delivery of the TPU melt to the die head, thereby guaranteeing product quality and dimensional accuracy.

Features: TPU melt pumps operate under high-pressure (40MPa) and high-viscosity (40,000Pa・s) conditions. Their flow channels feature near-mirror-like smoothness, making them suitable for heat-sensitive TPU materials. Additionally, the pumps boast precision construction with high-accuracy temperature control. Optimized flow channels and lubrication systems provide self-cleaning functionality, eliminating residual material and dead spots.

Features: TPU melt pumps operate under high-pressure (40MPa) and high-viscosity (40,000Pa・s) conditions. Their flow channels feature near-mirror-like smoothness, making them suitable for heat-sensitive TPU materials. Additionally, the pumps boast precision construction with high-accuracy temperature control. Optimized flow channels and lubrication systems provide self-cleaning functionality, eliminating residual material and dead spots.

Function: The screen changer is a melt filtration device installed at the extruder outlet. Its core function is to filter and trap impurities in molten TPU material, such as carbonized particles, metal shavings, gels, and unplasticized raw material. This enhances product purity, optical properties, and mechanical strength while ensuring continuous production.

Working Principle: Under pressure, the TPU melt passes through the screen changer chamber equipped with a high-precision filter screen. Impurities are blocked by the screen, while pure material flows smoothly to the next process stage.

Selection Criteria: When selecting a screen changer, calculate the required filtration area based on production capacity needs and material characteristics to determine the appropriate specifications. Additionally, consider production requirements for pressure stability, automation level, screen change frequency, cost budget, and maintenance convenience.

Email: sale@meltpump.com

WhatsApp: +86 158 3833 1071

Any questions about our products, please feel free to contact us! We promise you high-end products and first-class service.Look forward to our cooperation!!!

- sales@battemachinery.com

- +0086-371-67991755