- Position:

- Batte Melt pump > NEWS >

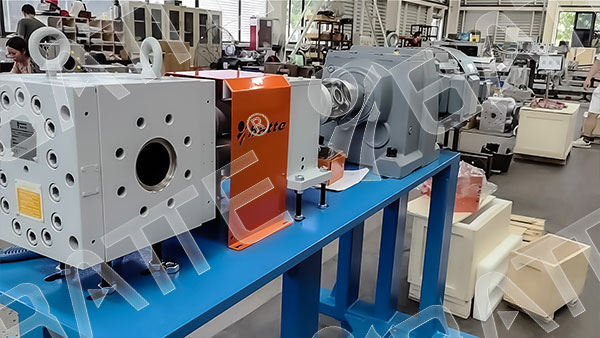

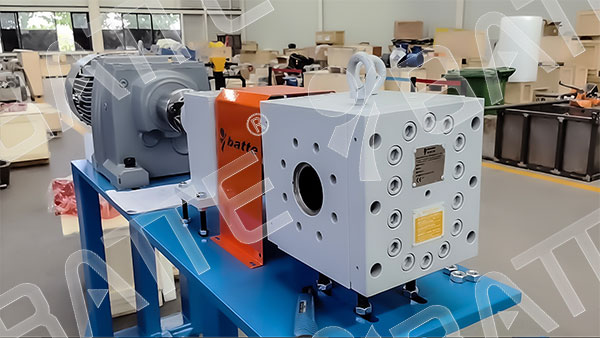

Double shaft drive melt pump

In the field of polymer material processing, the twin-shaft driven melt pump has become a key piece of equipment for enhancing production efficiency and product quality due to its unique design. This analysis delves into its core advantages across three dimensions: mechanical performance, conveying capability, and operational stability. Drawing on the technical practices of leading enterprises like Zhengzhou Bate, it showcases the pump's outstanding performance in high-end applications such as HDPE double-wall corrugated pipes.

1. Mechanical Performance Advantages: Dual-Shaft Synergy Doubles Lifespan

Conventional single-shaft pumps subject gear bearings to simultaneous radial forces and torque loads, leading to fatigue wear during prolonged operation and shortened equipment lifespan. The dual-shaft drive melt pump employs a synchronized counter-rotation design, allowing radial forces on both shafts to cancel each other out. Consequently, gear bearings bear only torque loads. This innovation significantly reduces single-shaft loading, minimizes fatigue failure risks, and extends equipment lifespan by over 30%. In continuous HDPE double-wall corrugated pipe production lines, the reliability of dual-shaft pumps is particularly outstanding. For instance, Zhengzhou Bate's customer case demonstrates equipment capable of operating continuously for over 8,000 hours without failure, substantially reducing maintenance costs and production interruption risks.

2. Advantages in Conveying Performance: High-Pressure Feeding, Efficiency Leap

The symmetrical flow channel design of the twin-shaft drive melt pump substantially enhances volumetric efficiency. At identical rotational speeds, flow rates increase by 20%-40% compared to single-shaft pumps, with output pressure stability maintained at ±0.5%. Its precision gear meshing effectively minimizes internal melt backflow, significantly improving delivery efficiency. This feature is particularly suited for producing large-diameter, thick-walled pipes, rapidly meeting die head demands for high-pressure melt feeding.

3. Operational Stability: Pulsation Suppression, Quality Assurance

The symmetrical dual-shaft layout combined with high-precision gear machining completely eliminates flow pulsation inherent in traditional single-shaft pumps. Test data confirms pressure fluctuation ≤1%, far below the 5%-8% range of single-shaft pumps. This stability effectively protects downstream dies and pipelines, preventing uneven product thickness caused by melt pulsation.

Technical Extensions and Application Value:

The advantages of dual-shaft drive melt pumps extend beyond equipment performance to direct production benefits. For instance, in HDPE pipe manufacturing, their series operation with extruders reduces back pressure by 40% and boosts output by over 20%. This makes them particularly suitable for applications demanding high dimensional accuracy, such as municipal water supply/drainage pipes and chemical transport pipelines.

Email: sale@meltpump.com

WhatsApp: +86 158 3833 1071

Any questions about our products, please feel free to contact us! We promise you high-end products and first-class service.Look forward to our cooperation!!!

- sales@battemachinery.com

- +0086-371-67991755