- Position:

- Batte Melt pump > NEWS >

Hot Melt Adhesive Melt Pump

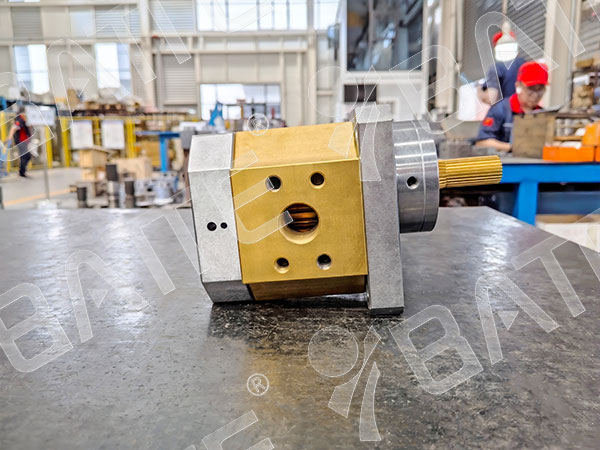

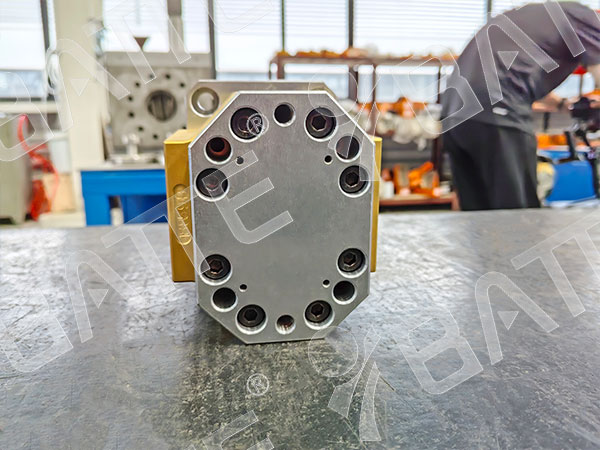

Hot melt adhesive pumps are positive displacement pumps that convey melt by altering the working volume through the meshing of drive and driven gears during operation. The working volume is formed by the pump body, gear tooth cavities, and bearing sleeves that function as side plates. As the gears rotate, the melt enters the suction chamber between the gear teeth. During rotation, the melt is drawn into the discharge chamber from both sides. When the gears re-engage, the melt in the tooth cavities is squeezed out of the discharge chamber and forced into the outlet pipeline. Standard lubricating grease cannot be used on the bearings to avoid contaminating the melt; instead, the melt itself provides self-lubrication.

The structure of a hot melt adhesive pump comprises a pump housing, drive gear, driven gear, slide bearings, front and rear end plates, packing seals, and other components. Within the hot melt gear pump, the sealing structure plays a critical role. It employs high-temperature-resistant packing seals or other sealing methods to ensure no leakage of the melt during pumping. Additionally, the pump body, front and rear end plates, and other components collectively form the pump's framework, providing a stable operating environment for the gears. Notably, hot melt gear pumps are typically equipped with heating systems, such as electric heating or thermal fluid jackets, to maintain the adhesive at an optimal temperature during pumping. This helps ensure the adhesive's flowability and stability, enhancing pumping efficiency.

Features of Hot Melt Pumps

1. Stable Flow and Linear Output: Hot melt pumps exhibit minimal pressure-flow pulsation, enabling linear flow output. This makes them particularly suitable for systems requiring precise extrusion, ensuring stable output to meet high-precision processing demands.

2. Rotor Design: The rotor of a hot melt adhesive pump is typically forged from solid alloy steel, with the tooth surfaces nitrided. This provides high strength, wear resistance, and corrosion resistance, thereby enhancing the pump's service life and stability.

3. Precision Control: Utilizing variable-frequency motor drive with thermal oil heating and cooling, the pump enables precise regulation of pressure, speed, flow rate, and temperature. This control accuracy maintains stable polymer melt conditions, further enhancing application performance.

4. Optimized Melt Flow Path Design: Eliminating dead zones within the flow path effectively reduces polymer residue, thereby improving product quality.

5. Multiple Mounting Options: The hot melt adhesive pump offers various installation configurations to meet customized user requirements.

6. Compact Structure and High Efficiency: Compared to other gear pump types, it features a compact design, reliable operation, low energy consumption, and high volumetric efficiency. Under high-viscosity and high-pressure conditions, it maintains stable flow rates without outlet pressure fluctuations.

Email: sale@meltpump.com

WhatsApp: +86 158 3833 1071

Any questions about our products, please feel free to contact us! We promise you high-end products and first-class service.Look forward to our cooperation!!!

- sales@battemachinery.com

- +0086-371-67991755