- Position:

- Batte Melt pump > NEWS >

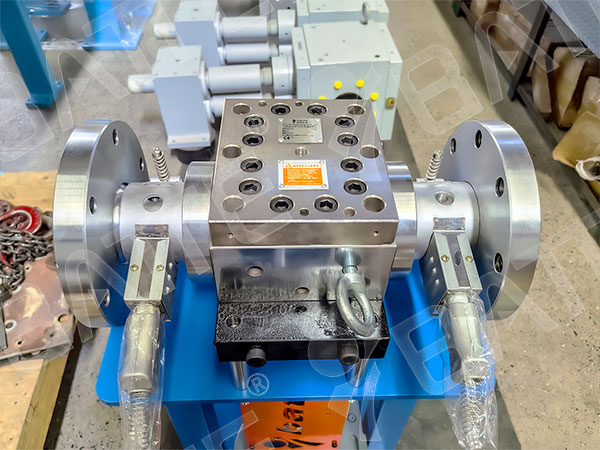

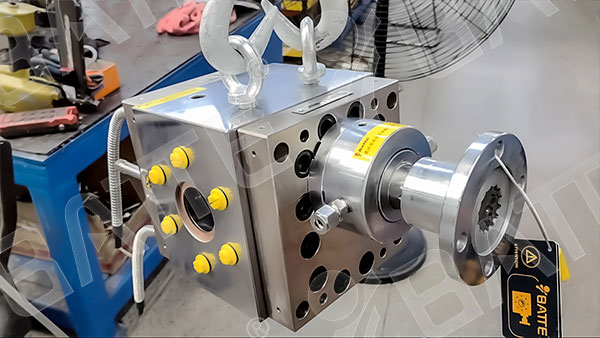

Why has the melt pump outlet pressure decreased?

The core reasons for reduced melt pump outlet pressure can be categorized into three types: insufficient feed supply at the inlet end, pump body malfunction, and reduced load at the outlet end. Detailed analysis follows:

Insufficient Feed Supply at the Feed End

Extruder Feeding/Plasticizing Abnormalities: Material shortage in the extruder hopper, screw wear reducing conveying capacity, or poor raw material plasticization (low temperature, excessive moisture content) can cause material shortage on the melt pump's suction side, preventing sufficient pressure buildup.

Feedline Blockage / Throttling: Partial blockage in the melt pump inlet filter or connecting lines, or an inlet valve not fully open, restricts melt flow into the pump chamber. This reduces the pump's effective suction volume and lowers outlet pressure.

Raw Material Property Fluctuations: A sudden increase in the raw material's melt flow rate (MFR) reduces melt viscosity. At the same rotational speed, the pump's pressure-building capability weakens.

Melt Pump Malfunction

Internal Wear/Leakage: Increased clearance between gears and pump chamber/end faces in gear pumps due to prolonged operation, or wear between screws and bushings in screw pumps, increases internal melt backflow, preventing outlet pressure maintenance.

Drive System Abnormalities: Reduced motor speed, inverter failure, or coupling slippage causes actual pump speed to fall below set values, reducing melt output and lowering pressure.

Seal failure: Damage to sealing components like shaft seals allows melt leakage outside the pump body, causing outlet pressure to drop.

Reduced discharge-end load

Downstream equipment throttling reduction: Decreased screen clogging in screen changers, unobstructed die channels (e.g., after die blockage clearance), or reduced downstream pipeline resistance lower melt discharge resistance, resulting in decreased outlet pressure.

Downstream equipment malfunction: Improperly seated screen after screen changer switching, die leakage, or excessively high speeds in subsequent haul-off/winding equipment can cause melt discharge to exceed pump delivery, resulting in pressure drop.

Troubleshooting Recommendations

Prioritize checking the feed end: Verify extruder hopper material level and raw material plasticization temperature. Dismantle the inlet filter to inspect for blockages.

Next, inspect the pump assembly: Observe whether motor speed is normal and check for coupling slippage. If internal wear is suspected, shut down the machine for disassembly and clearance measurement.

Finally, examine the discharge end: Inspect the condition of the screen changer filters and check for die leakage. Confirm that downstream equipment operating parameters are properly matched.

Email: sale@meltpump.com

WhatsApp: +86 158 3833 1071

Any questions about our products, please feel free to contact us! We promise you high-end products and first-class service.Look forward to our cooperation!!!

- sales@battemachinery.com

- +0086-371-67991755