- Position:

- Batte Melt pump > NEWS >

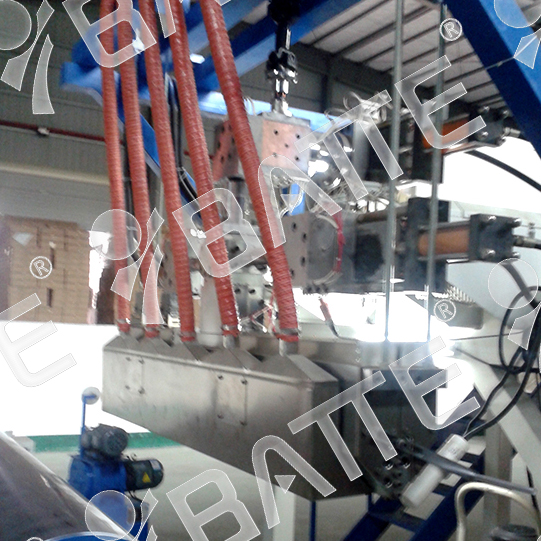

plastic film extrusion melt pump

The plastic film extrusion melt pump is a critical piece of equipment in the production of plastic films. Operating on the principle of positive displacement conveyance, it achieves stable pressurization, metering, and conveyance of high-temperature melts, offering significant advantages in enhancing film quality, production efficiency, and energy conservation. Below is an analysis focusing on its structure, functions, applications, and key considerations for selection and usage:

I. Structure and Working Principle

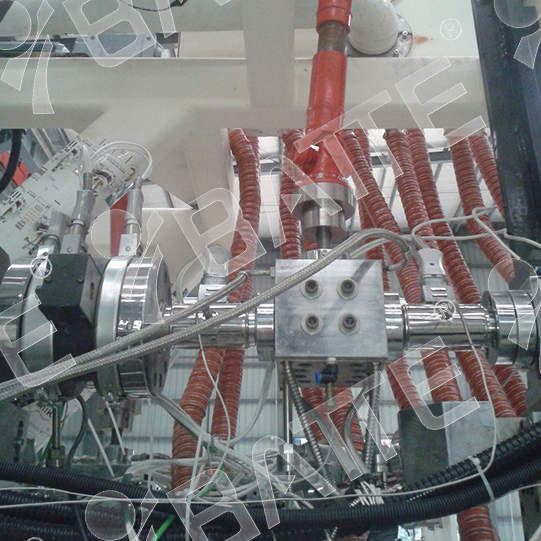

The plastic film extrusion melt pump typically consists of components such as a pump body, driving gear, driven gear, sliding bearings, front and rear end plates, and sealing assemblies. Its working principle is based on the meshing motion of gears:

Feeding Zone: The melt enters the gear tooth spaces, and as the gears rotate, they carry the melt into the conveying zone.

Conveying Zone: The melt is transported by the gears to the discharging zone.

Discharging Zone: The gears mesh again, forcing the melt into the outlet pipeline. Through the rotation of the gears, the melt is steadily conveyed to the extrusion die head, forming a continuous and uniform film.

II. Core Functions and Advantages

Stable Extrusion and Precise Metering

The melt pump, through positive displacement conveyance, ensures a strictly proportional relationship between flow rate and rotational speed, eliminating flow instability issues caused by temperature fluctuations and screw speed pulsations in the extruder.

In film production, it significantly reduces dimensional tolerances, improves film thickness uniformity, and lowers the scrap rate.

Pressurization and Pressure Stabilization

As an efficient pressurization device, the melt pump reduces the die head pressure on the extruder screw, minimizes melt temperature fluctuations, and extends the screw's service life.

It maintains a stable extrusion volume even under high die head pressures, preventing melt leakage.

Energy Conservation and Consumption Reduction

The extruder operates at lower pressures and temperatures, reducing leakage flow and increasing output.

When combined with twin-screw extruders, it significantly enhances mixing quality and output while reducing energy consumption by approximately 25%.

Simplified Process Flow

Installing a melt pump on single-screw or twin-screw extruders enables direct extrusion of products, eliminating the pelletizing step and shortening production cycles.

It is suitable for film production using blended and modified materials, simplifying the process flow.

III. Applications

Precision Film Production

In the production of high-precision films such as optical films and capacitor films, the melt pump ensures film thickness uniformity, meeting stringent quality requirements.

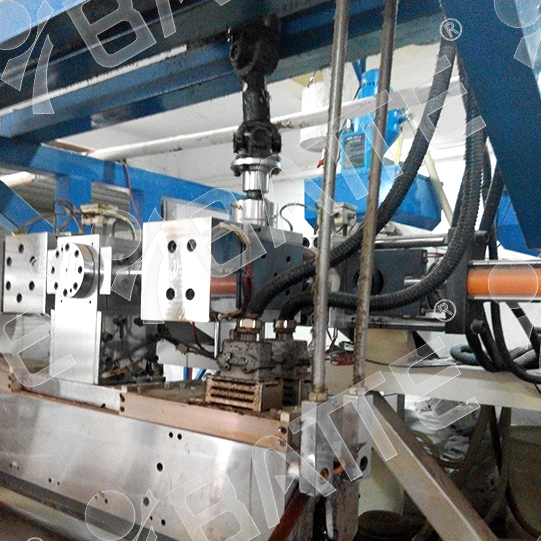

Large-Scale Product Extrusion

By simultaneously supplying melt to the melt pump from multiple small to medium-sized extruders, large-diameter pipes and wide-width films can be produced, enhancing production efficiency.

Energy-Saving and Consumption-Reducing Retrofits

Installing a melt pump on existing extrusion lines significantly reduces energy consumption and improves production efficiency.

IV. Key Considerations for Selection and Usage

Viscosity and Temperature Adaptability

The melt pump must adapt to the viscosity range (typically 1–40,000 Pa·s) and temperature requirements (≤350°C) of the film material.

The sealing structure should be selected based on material characteristics, such as melt dynamic seals, packing seals, or mechanical seals.

Pressure and Flow Rate Matching

The output pressure must meet the process requirements for film extrusion (typically 0–40 MPa), and the flow rate should match the extruder's capacity.

Material and Wear Resistance

The pump body, gears, and bearings must be made of high-temperature and corrosion-resistant materials, such as stainless steel, alloy steel, or corrosion-resistant alloys.

Under high-filling conditions, wear-resistant coatings can be applied to extend the equipment's service life.

Installation and Maintenance

During installation, ensure the concentricity of the pump shaft and the motor drive shaft to avoid vibrations and additional stresses.

Regularly inspect the wear conditions of seals, gears, and bearings, and promptly replace vulnerable components.

Email: sale@meltpump.com

WhatsApp: +86 158 38331071

Any questions about our products, please feel free to contact us! We promise you high-end products and first-class service.Look forward to our cooperation!!!

- sales@battemachinery.com

- +0086-371-67991755