- Position:

- Batte Melt pump > NEWS >

The critical role of melt pumps in polymer extrusion molding

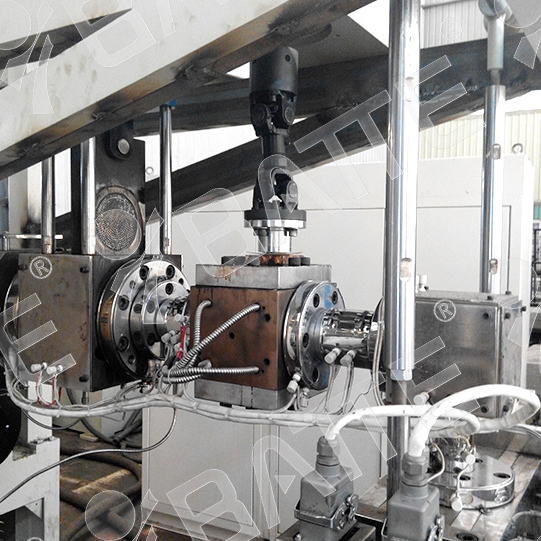

Melt pumps are a kind of power equipment used for conveying high temperature and high viscosity polymer melts, and play a key role in the extrusion molding process of plastics, resins, rubbers, and chemical fiber products. The following is an overview of its functions and applications:

In terms of function, melt pump is mainly used for conveying, pressurizing and metering of high temperature and high viscosity polymer melt. It can pressurize and stabilize the high temperature plastic melt from the extruder, and then the flow rate is steadily fed into the extruder head, and its ability to stabilize the melt pressure and flow rate is superior to that of various types of extruders. The melt pump can also effectively block the pressure fluctuation in the feeding area and the influence of flow fluctuation on the discharging area to realize stable flow delivery. In addition, by adjusting the pump speed, melt pumps allow for precise flow control, which is essential for producing high quality products.

In terms of application, melt pumps are widely used in extrusion molding of plastic, resin and rubber products, such as pelletizing, film, pipe, plate, sheet, man-made fibers, optical fibers, and medical plastic catheters. It can be used in tandem with single-screw or coaxial twin-screw extruders to significantly improve the efficiency of the whole production line. In addition, combining the isotropic twin-screw extruder and melt pump to form a mixing extrusion pelletizing line, its mixing quality and output are greatly improved than that of a separate twin-screw pelletizing unit, and energy consumption is reduced at the same time. In the original is a single-screw or isotropic twin-screw pelletizing extruder on the addition of melt pumps and pipe, plate, film and other extruder head, but also eliminate the pelletizing process directly extruded products, simplify the production process, shorten the production cycle.

In general, the melt pump with its stable delivery, precise control, high efficiency and energy saving features, in the plastic, resin, rubber and other products in the extrusion molding process plays an important role for the relevant industries has brought significant economic benefits.

Email: sale@meltpump.com

WhatsApp: +86 158 38331071

Any questions about our products, please feel free to contact us! We promise you high-end products and first-class service.Look forward to our cooperation!!!

- sales@battemachinery.com

- +0086-371-67991755