- Position:

- Batte Melt pump > NEWS >

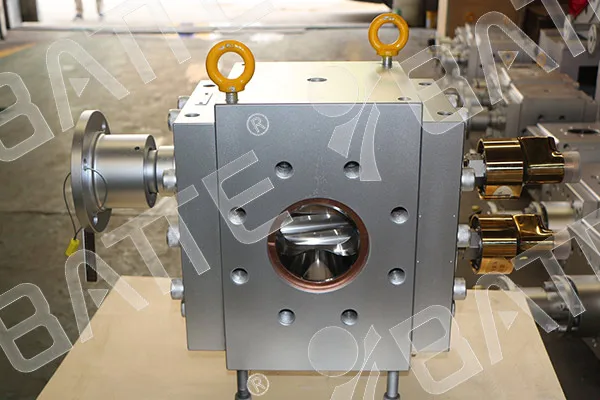

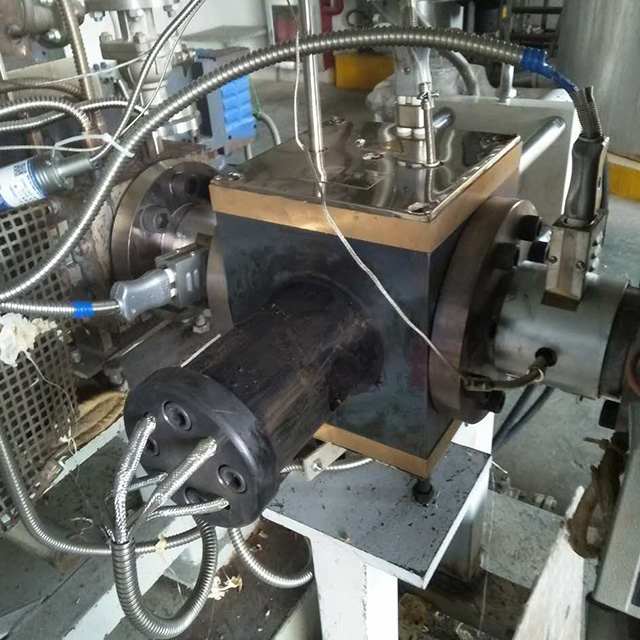

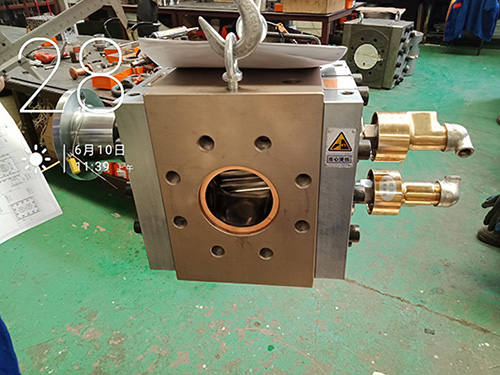

Why is a melt pump needed on an extruder?

There are several reasons why a melt pump is needed to be paired with an extruder:

Stable Pressure and Flow Rate:

A melt pump provides stable melt pressure and flow rate, preventing pressure fluctuations during the extrusion process. This is crucial for maintaining the stability of the extrusion process and ensuring product quality.

Control of Melt Pulsation:

The precise metering and control functions of the melt pump significantly reduce pulsations in the melt flow, which further improves the quality of the extruded product.

Homogenization of Melt:

During the process of conveying the melt, the melt pump shears and mixes the melt through the rotation of its internal gears or screws, thereby improving the uniformity and stability of the melt.

Reduction of Extruder Load:

Using a melt pump reduces pressure and temperature fluctuations at the feed end of the extruder, lightening the load on the extruder and extending its service life.

Improved Production Efficiency:

The melt pump's stable conveying and metering functions help reduce the residence time of materials in the screw cylinder, stabilizing the plasticization process and thus increasing the production efficiency of the extruder.

Enhanced Product Quality:

The melt pump reduces the dimensional tolerance of the extruded product, lowering the scrap and waste rate, enabling ordinary extruders to produce high-precision products.

Energy Savings:

By improving mixing quality and output, the melt pump reduces the energy consumption per kilogram of material processed.

Reduction of Backflow and Temperature Fluctuations:

The rotation and engagement of the gears can seal the low-pressure cavity, reducing backflow and lowering processing temperatures, which is beneficial for establishing a higher output pressure.

Increased Output:

The addition of a melt pump to the extrusion system can significantly increase product output.

In summary, the melt pump plays a vital role in the extrusion process by providing stable pressure and flow rate, controlling melt pulsation, homogenizing the melt, reducing extruder load, improving production efficiency and product quality, saving energy, and increasing output. It is an essential component for achieving efficient and economical production.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071

Any questions about our products, please feel free to contact us! We promise you high-end products and first-class service.Look forward to our cooperation!!!

- sales@battemachinery.com

- +0086-371-67991755