- Position:

- Batte Melt pump > NEWS >

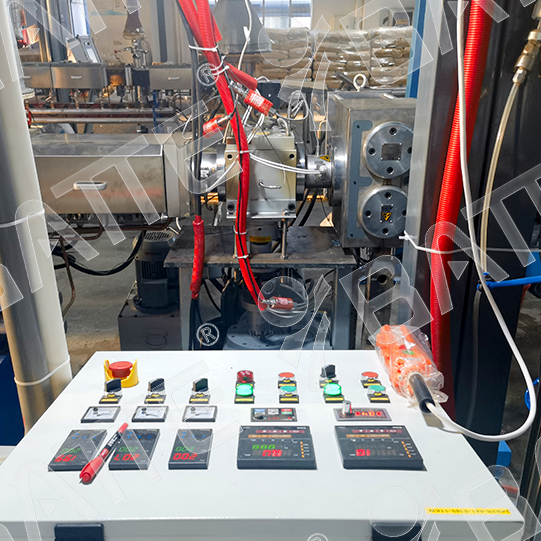

PVC granulation melt pump

The PVC Granulation Melt Pump is a dedicated device for conveying, pressurizing, and metering high-temperature, high-viscosity melts during the PVC granulation process. Below is a detailed introduction to the PVC Granulation Melt Pump:

I. Equipment Composition

The PVC Granulation Melt Pump mainly consists of a pump body, front and rear side plates, two intermeshing gears, bearings, and seals. The tooth profiles of the two gears, the pump body, and the side plates collectively form the pump's inlet zone, conveying zone, and discharge zone.

II. Working Principle

When the gears rotate in the prescribed direction, PVC melt enters the tooth spaces of the two gears in the inlet zone. As the gears rotate, the melt is carried into the conveying zone from both sides. When the gears mesh again, the melt in the tooth spaces is squeezed out into the discharge zone and pressed into the outlet pipeline. Due to the continuous rotation of the pump shaft, the gears continuously press the melt towards the outlet side, allowing the pump outlet to reach high pressures.

III. Application Advantages

Precise Metering and Stable Conveyance: The PVC Granulation Melt Pump can precisely meter and stably convey PVC materials that have undergone initial mixing and melting, making the granulation process more efficient and stable, and producing PVC granules of uniform quality.

Increased Production Efficiency: The melt pump can stabilize and pressurize high-temperature, high-viscosity PVC melt and then stably feed it into the extruder die, thereby increasing production efficiency.

Optimized Flow Channel Design: The PVC Granulation Melt Pump typically features an optimized flow channel structure that eliminates dead corners within the flow channel, minimizes polymer residue, and improves product purity and quality stability.

Adaptability to PVC Thermosensitivity: Considering PVC's thermosensitivity, the melt pump often adopts a bell-shaped inlet flow channel, with optimized internal flow channels and gear structures. Additionally, it features built-in melt self-lubrication, allowing lubricating material to be discharged with the material, preventing carbonization, decomposition, or scorching of the material due to temperature changes during extrusion.

Improved Gear Parameters: More precise displacement design stabilizes the output pressure, effectively adapts to precision extrusion requirements, and reduces product defects caused by pressure fluctuations.

Nearly Linear Flow Output: The PVC Granulation Melt Pump can achieve nearly linear flow output, making it easy to control and better coordinate with upstream and downstream equipment. It precisely controls the melt conveyance volume according to production demands.

IV. Application Fields

PVC Granulation Melt Pumps are widely used in the production process of PVC granules, providing high-quality raw materials for subsequent plastic product processing. They are also widely applied in production lines for chemical fibers, plastic films, sheets, plates, profiles, wires and cables, wire drawing, and composite extrusion.

In summary, PVC Granulation Melt Pumps play a crucial role in the PVC granulation process, offering advantages such as precise metering, stable conveyance, increased production efficiency, optimized flow channel design, adaptability to PVC thermosensitivity, improved gear parameters, and nearly linear flow output.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071

Any questions about our products, please feel free to contact us! We promise you high-end products and first-class service.Look forward to our cooperation!!!

- sales@battemachinery.com

- +0086-371-67991755