- Position:

- Batte Melt pump > NEWS >

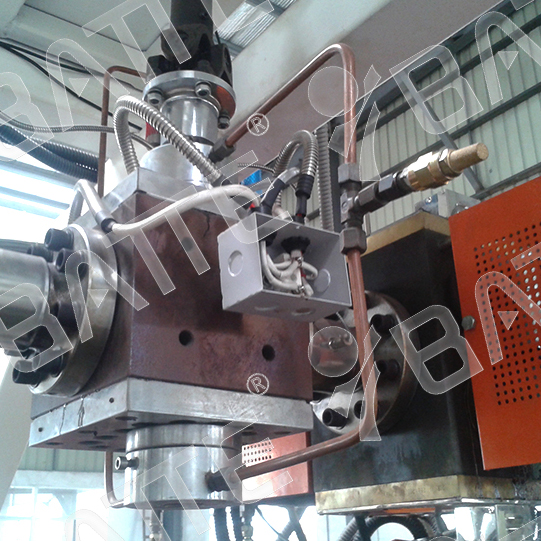

polymer melt pump for XPS plant

In an XPS (extruded polystyrene) plant, a polymer melt pump is a critical component of the extrusion process. This pump is specifically designed to handle the high-temperature, high-viscosity polymer melt that is essential for producing XPS foam boards.

Function of a Polymer Melt Pump:

Pressure Control: The melt pump provides precise control over the pressure of the polymer melt as it is extruded. This is crucial for maintaining consistent product dimensions and ensuring uniform cell structure in the XPS foam.

Flow Rate Stability: By regulating the flow rate of the melt, the pump helps to achieve a steady and continuous extrusion process. This stability is essential for producing XPS boards with consistent thickness and density.

Enhanced Processing Efficiency: The melt pump enables efficient mixing and homogenization of the polymer melt, which can improve the overall processing efficiency and reduce energy consumption.

Adaptability: Polymer melt pumps can be adjusted to accommodate different types and grades of polystyrene, allowing for flexibility in production and the ability to meet varying customer demands.

Durability and Reliability: These pumps are built to withstand the harsh conditions of the extrusion process, including high temperatures and pressures, ensuring long-term reliability and minimal downtime.

In summary, a polymer melt pump for extruder is an indispensable piece of equipment in an XPS plant. It plays a vital role in controlling the pressure and flow rate of the polymer melt, enhancing processing efficiency, and ensuring the production of high-quality XPS foam boards.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071

Any questions about our products, please feel free to contact us! We promise you high-end products and first-class service.Look forward to our cooperation!!!

- sales@battemachinery.com

- +0086-371-67991755