- Position:

- Batte Melt pump > NEWS >

PP corrugated plate extrusion melt pump

PP hollow corrugated sheet production line realizes the continuous production of PC/PE/PP hollow grid board, which is suitable for building decoration, advertising placement, highway sound insulation, packaging, etc. PE/PP hollow grid board is an ideal substitute for paper boxes to make packaging boxes. It has the characteristics of light weight, high strength, moisture-proof and anti-corrosion. The width of the product is 1220-2100mm and the thickness is 2mm-12mm.

PP hollow corrugated sheet production line realizes the continuous production of PC/PE/PP hollow grid board, which is suitable for building decoration, advertising placement, highway sound insulation, packaging, etc. PE/PP hollow grid board is an ideal substitute for paper boxes to make packaging boxes. It has the characteristics of light weight, high strength, moisture-proof and anti-corrosion. The width of the product is 1220-2100mm and the thickness is 2mm-12mm.

How does Corex Sheet melt pump achieve the purpose of melt conveying?

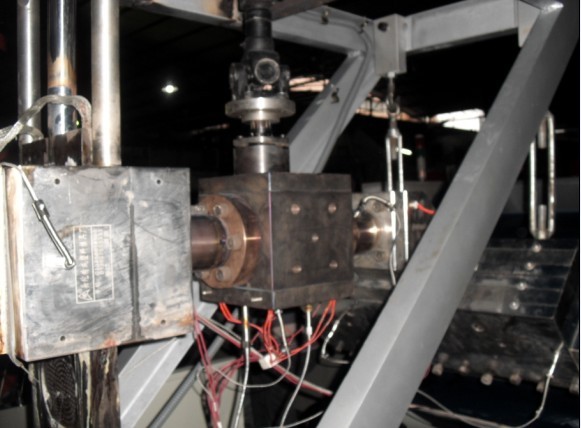

PP coroplast sheet extrusion melt pump achieves melt delivery through the working volume change caused by the process of gear meshing with each other. When the gears of the melt gear pump mesh with each other, the gap between the gears and the inner hole surface of the shell is very small, and the gap between the gear end face and the cover is also very small, thus separating the inhalation cavity and the press-out cavity. When the gears rotate, the teeth engaged on the left side of the meshing point gradually withdraw from the meshing, and the space increases, forming a local vacuum, sucking the liquid into the inhalation cavity continuously, and the teeth on the right side of the meshing point gradually enter the meshing and squeeze out the liquid between the teeth. The process is that when the active wheel drives the driven wheel rotation, in the suction port plastic melt filled between the teeth, the top circle radius of the gear sweeps through a certain volume, plastic melt along the pump body surface is taken to the discharge chamber. From the two gears out of the plastic melt in the discharge chamber converge with each other, most of which are squeezed into the pump outlet, only a small part of the return to the suction chamber. As the gears of the melt gear pump continue to suck in and discharge, so as to achieve the purpose of transporting melt.

The melt gear pump used in the plastic extrusion system is usually a three-piece combined structure, which is composed of two mutually meshing active and passive gears, the middle pump body, both sides of the pump cover and the external heating and cooling device of the pump body. The plastic melt with high viscosity and poor flowability is conveyed to the head through the flow channel. The melt pump designed and developed by Zhengzhou Batte melt pump manufacturer is used in extrusion system with the advantages of pressure stabilization, metering and improving the production capacity of extruder; it is widely used in the extrusion of plastic, resin and rubber products. batte melt pump has served many countries and regions in the world, such as Europe, India, Vietnam, Pakistan, Qatar, Africa and Latin America countries.

Email: info@battemachinery.com

Whatsapp: +86 158 38331071

Any questions about our products, please feel free to contact us! We promise you high-end products and first-class service.Look forward to our cooperation!!!

- sales@battemachinery.com

- +0086-371-67991755