- Position:

- Batte Melt pump > NEWS >

The working condition of the sliding bearing affects the efficiency of the melt pump

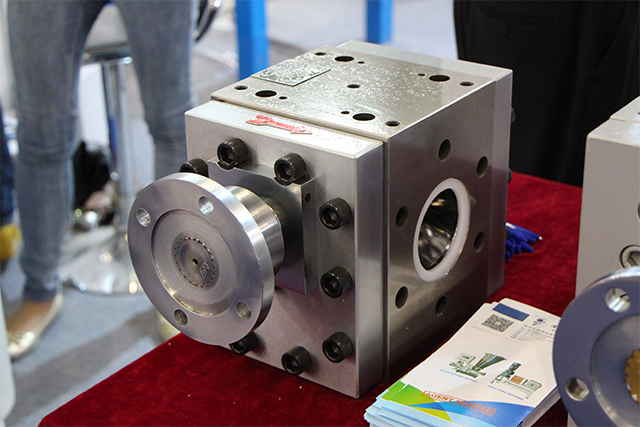

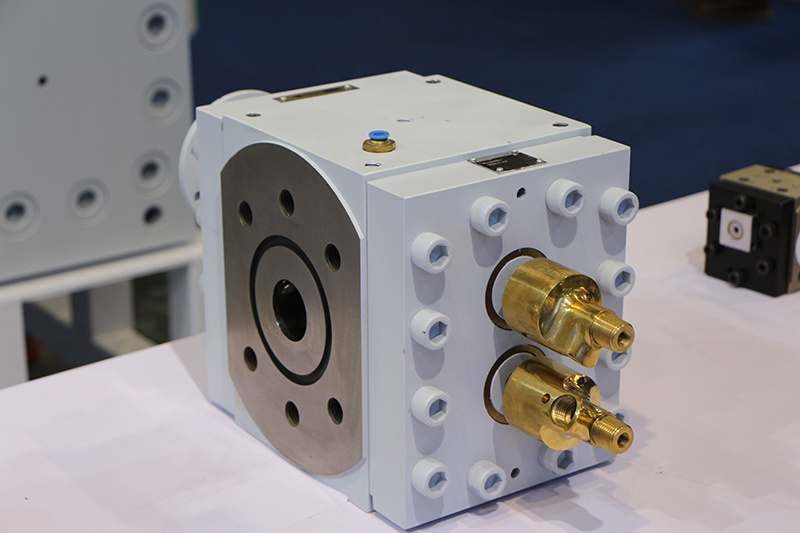

Working principle of melt booster pump: Polymer melt booster pump is a positive displacement pump, and it relies on the change of working volume caused by the meshing of the main and driven gears to transport the melt. The working volume is composed of the pump body, the tooth groove of the gear and the bearing with the function of the side plate. When the gear rotates, the melt enters the tooth grooves of the two gears in the suction cavity. As the gear rotates, the melt is brought into the discharge cavity from both sides, and the gear meshes again, so that the melt in the tooth groove is squeezed out and discharged. The cavity is pressed to the outlet pipe. As long as the pump shaft rotates, the gear will pressure the melt to the outlet side, so the pump outlet can reach a very high pressure, and the flow rate is basically independent of the discharge pressure.

The better working condition of the sliding bearing of the melt pump should be that a relatively uniform liquid film can be formed on the inner surface of the drive shaft and the sliding bearing. The liquid film can completely separate the two metal surfaces of the shaft and the sliding bearing. Will play a role in supporting the axle load. When the melt pump stops running, the journal will be in the lower part of the sliding bearing, and the two metal surfaces are in direct contact. There is no melt for lubrication in the gap between the shaft and the bearing. The bearing is in dry friction at the beginning.

When the conveyed melt increases and the outlet pressure gradually increases, under the action of the pressure difference between the outlet and the inlet, part of the melt enters the bearing gap from the guide groove. As the shaft rotates evenly, the shaft and the bearing surface will form a gap. The thin film formed by this kind of melt, at this time, the friction of the two metal surfaces gradually decreases. When the melt film fully supports the vertical load of the rotating shaft, the frictional resistance of the bearing is only the viscous resistance of the melt. At this time, close to the liquid lubrication state, the friction factor of the two metal surfaces will reach the ideal state. . Therefore, it is impossible to achieve the ideal lubrication state under limited load.

The failure modes of sliding bearings are mainly abrasive wear and adhesive wear. The higher the outlet pressure of the melt pump, the greater the shear force of the shaft on the lubricating film, the more serious the damage of the lubricating film, the closer the bearing area will be to mixed friction, and sometimes it is even in a state of dry friction. The more severe the bearing surface damage. When the wear on the inner surface of the shaft and the sliding bearing is close to the thickness of the hardened layer, do not simply scrap it once (you can re-grind the shaft and use it again), but only need to replace a new set of sliding bearings, because the price of the shaft is a few of the bearing price. In this way, the life of the pump shaft can be prolonged. info@battemachinery.com

Any questions about our products, please feel free to contact us! We promise you high-end products and first-class service.Look forward to our cooperation!!!

- sales@battemachinery.com

- +0086-371-67991755