- Position:

- Batte Melt pump > NEWS >

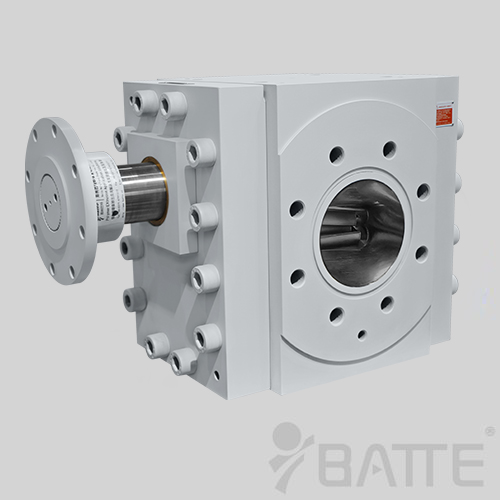

Extruder melt pump - external lubrication pump

Extruder melt pump - external lubrication pump

The pump works as follows: the gear motor is connected with the flange is fixed to the pump element driven by the eccentric drive shaft fork slide linearly reciprocated and rotated by the oil pressure plate and a spiral scraper plate in the clockwise direction (with lubrication Oil is no such institution), softened by stirring grease evenly around the mouth is pushed to the suction melt pump components. There are two sets of piston pump body, each one by a working piston and a control piston 2 and putt 3 components.

When a group of the working piston in the piston suction process is completed, another group of the working piston in the piston to put the grease outlet port; the oil, the piston 1, the control piston 2, the rightward movement of the plunger 3, the piston 2 Under the action of the spring reaches the limit position, continued rightward movement of the piston 1, when a vacuum is formed between a piston 2 and a piston, the piston 1 reaches the right limit position, the suction port opens, the grease suction from the suction port, such as insufficient spring force, there is no pressure to limit the position of the piston 2, 3 putt slip in under the fork piston driven forcibly pushed to the limit position 2. When the piston 1 moves to the left, the first suction port is closed, inhaled Run

Grease to the left under the impetus of the piston 1, when the piston 2 opens the port, the movement will stop, then continued leftward movement of the piston 1 and the pressure of the grease from the oil outlet. When the piston is in contact with a piston 2, the movement is stopped. This cycle to cycle, the two groups will grease the piston alternately pressure from the oil port to send out. The pressure of the lubricant pump is connected to the flange member of the filter medium supplying system.

Safety valve to protect the pump and the pressure lubrication system pressure does not exceed the normal requirements. Right-handed counter-pressure adjustment screw may increase, L is reduced. If the system overpressure valve failed to open, with the insurance piece overpressure safety device that automatically blasting, unloading pump, which pumps from damage.

Capacity indicator can send signals at the highest or lowest oil level, (through electrical control box converts sound and light signals) the token can also be controlled electric pumps work.

The initial operating pressure relief valve has been adjusted at the factory setting. You can increase or decrease the pressure relief valve action. Maximum working pressure is 40Mpa.

Use essentials:

1 lubrication pump should be mounted vertically for easy maintenance and fixed in place and dust less, and pay attention to the ambient temperature is suitable pump operating temperature range.

2 pump as mounted in the center of the lubrication system and shorten the length of the pipe system to maintain a minimum pressure drop, in order to ensure that the pump generates a back pressure sufficient to overcome the pressure of the lubrication point.

3 Set the pump pressure relief valve can be adjusted within the range of 0 ~ 40Mpa, when used must not exceed the nominal pressure pump (40Mpa).

4. The oil filter at the mouth of the pump filter should be cleaned regularly to prevent clogging.

5 If for some reason the failure of the system, so that the pressure to reach 50Mpa, the insurance piece that is broken, and to identify the reasons for exclusion before loading new insurance piece.

6 oil reservoir to replenish the lubricant must use electric pumps oil from the reservoir to join complement fat mouth.

7 films in the oil storage capacity gauge only applies grease to use when lubricating medium must be swapped into a float capacity indicator.

8 electric gear early with the right amount of 3 months must be added # molybdenum disulfide grease from the vent plug hole, replenished once every four months later.

9 The series of electric lubrication pump is mounted indoors, outdoors or in harsh environments occasions, protective measures must be taken.

Any questions about our products, please feel free to contact us! We promise you high-end products and first-class service.Look forward to our cooperation!!!

- sales@battemachinery.com

- +0086-371-67991755