- Position:

- Batte Melt pump > NEWS >

Why more gear tooth is inclined

Why more gear tooth is inclined? There are three reasons

1, A peace tooth compared to the position of the axis is more freedom. For example, the differential with helical bevel gear shaft and the rear axle is not necessarily at the same l, evel, if the bevel is flat, then it is a must.

2, noise reduction, helical gear speeds in the same noise level is too small teeth. The reason is that the first helical surface of the contact point, and then transition to the contact surface, the final contact point. Flat tooth surface contact line is the line. Helical toothed smoother transition. Therefore, a lot of noise because of the sudden change in contact levels generated by small gear ratio.

3, the production of convenience, with hobbing on cylindrical billet can produce a teeth number, modules the same face width different set of helical late into different face width can be based on customer demand.

The disadvantage is that because the force generated oblique axial force, ordinary ball needle are not competent. To use a pair of roller bearings angled (paired angle roller bearing) or thrust bearing.

In fact, application engineering helical gears are the majority, it is compared to the high temperature gear pump

A good meshing characteristics. From the point to the line, and then point meshing process smoother

B coincidence degree, while teeth into engagement more. Reduce the impact and noise, making the transmission more stable and can withstand high-speed heavy

C during processing, resulting in at least a small undercut teeth. Undercutting how to explain it simply, viewed from the axial end face of the gear, the gear normal contour of two adjacent teeth can be approximated as a <shape, and produce undercut tooth profile of α, that was more than cut the roots part of it. This results in reduced strength teeth, reducing the engagement surface Therefore, the helical gear is more reasonable for engineering practice. This will of course depend on the machining accuracy.

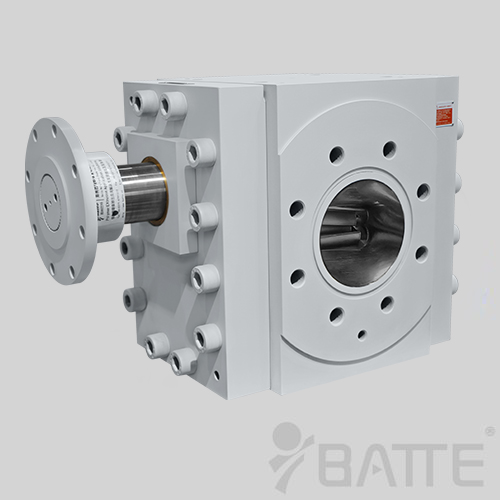

Zhengzhou Batte melt pump unique helical gear design.

Meshing spur gears is suddenly entered simultaneously along the entire width of the tooth meshing engagement and exit, so the force on the teeth is also a sudden plus or removed, so poor transmission smooth, shock and noisy; while a When helical gears, tooth profile surface of the contact line is oblique line, its front end face of the meshing process is driven wheel that came into contact with the top of the tooth, then the contact line by a short variable length, and then from the shorter length, the last in the rear face a point separating the driven tooth roots, so the force suffered a helical gear, but also from small to big, and then descending, so drive more stable, low impact and noise.

Besides coincidence degree helical gears, tooth contact in good condition, so the high load capacity; minimum helical gear teeth than spur gears is small, and therefore more compact bodies with spur gear manufacturing costs the same.

Because of these advantages, the use of helical gears are widely

Any questions about our products, please feel free to contact us! We promise you high-end products and first-class service.Look forward to our cooperation!!!

- sales@battemachinery.com

- +0086-371-67991755