- Position:

- Batte Melt pump > technic >

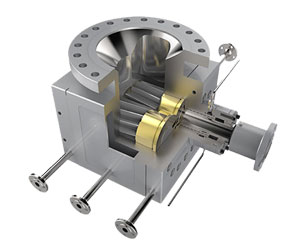

Melt pump seal

Melt pump seal include many types, such as single mechanical seal, vacuum mechanical seal, double mechanical seal, magnetic coupling - seal design, Viscoseal, Vakuum viscoseal with stuffing box, stuffing box, etc.

Melt pump seal methods:

Single mechanical seal: The single mechanical seal (ED) is the standard seal for chemical gear pumps. It is suitable for max. viscosity of 10 to 50 Pas.

Vacuum mechanical seal (AD), buffered: The single mechanical seal with buffered fluid (AD) in specially designed for vacuum conditions on the suction side. It is suitable for maximum viscosity of 100 Pas.

Double mechanical seal (DD), buffered: The double mechanical seal with buffered fluid (DD) is suitable for a max. viscosity of 1.000 Pas, because the internal parts of the mechanical seal do not get in contact with the pumped fluid. All the internal parts are lubricated by the buffer fluid. The pressure on the suction side can be within a wide range: from vacuum conditions to max. 15 bar.

Magnetic coupling - seal design: is in principle constructed in the same way as the chemical but with a synchronous magnetic coupling forming the shaft seal. This operates slip-free, i.e. the pump speed is always the same as the shaft speed, as long as the load torque does not exceed the nominal torque of the magnetic coupling.

Viscoseal: The viscoseal is a dynamic seal that can be heated or cooled. It is the standard seal for extrusion gear pumps. It is a dynamic sealing system. Its operative range is limited by the suction pressure and the viscosity of the fluid. The min. viscosity for this sealing system is approximate 10 Pas. To increase viscosity the viscoseal can be cooled.

Vakuum viscoseal with stuffing box:

The vacuum viscoseal with buffered stuffing box is the standard seal for polymer pumps. It is a combination of a dynamic (viscoseal) and a static (stuffing box) sealing system. The polymer flow back to the suction side is adjusted by a needle valve. The fluid barrier ensures that no air from the atmosphere gets in the pump/reactor. There is a buffered and heated stuffing box for back-up. To prevent failure/destruction of the packings, it is strongly recommended to heat the area of the stuffing box.

Stuffing box: The stuffing box is a simple seal for gear pumps. The operative range is similar to the viscoseal. It is suitable from low to high viscosities. The standard material for the packing rings is graphite (other materials are available). It is also available with buffered fluid and/or heating jacket.

All these melt pump seal methods are available, and they also depend on the melt pump types and applications.

Relative Articles:

◆Melt pumps

◆Melt discharge pumps for polymer production

◆Melt pump gear design

◆Melt pump for standard applications

◆Prepolymer melt pumps

Any questions about our products, please feel free to contact us! We promise you high-end products and first-class service.Look forward to our cooperation!!!

- sales@battemachinery.com

- +0086-371-67991755