- Position:

- Batte Melt pump > technic >

Consideration of Melt Pump and Extruder Integration

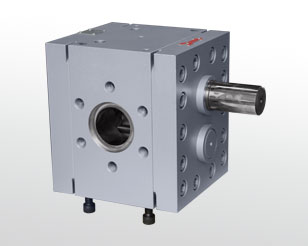

At present, melt pump has been widely used in the field of plastic extrusion, which is indispensable for its production. It can effectively improve production efficiency, reduce production energy consumption, and create greater production benefits for users. For the integration of melt pump and extruder, the following three factors should be considered, which is the guarantee of efficient production and operation after the integration of melt pump and extruder.

Consideration of power: Because the melt pump works according to the principle of volumetric conveying, the efficiency of the pump is very high, and the energy consumption in the input rubber is much smaller than that of the extruder which completes the same processing task, the power consumption or required torque of the extruder-melt pump unit system is much lower than that of the traditional cold feed extruder. Therefore, the extruder equipped with standard control power should also have a large torque margin for use. The newly developed extruder shaft makes use of these torque margins, so that unnecessary independent control mechanisms (motors, gearboxes and control systems) may be removed.

Mechanical design considerations for new equipment: In addition to the above requirements of direct drive of melt pump by extruder screw and strict compliance with the principle of volume axle feeding, the extruder must also be easy to install and disassemble. Because the motors, gearboxes and control systems used for individual drive are removed, the miniaturization of the whole set of equipment is realized naturally.

Any questions about our products, please feel free to contact us! We promise you high-end products and first-class service.Look forward to our cooperation!!!

- sales@battemachinery.com

- +0086-371-67991755