- Position:

- Batte Melt pump > NEWS >

Hot Melt Adhesive Gear Pump

Hot melt adhesive pumps are primarily used for conveying, pressurizing, and metering high-temperature, high-viscosity polymer melts. Their main function is to pressurize and stabilize high-temperature melts, ensuring precise and consistent melt flow into various pipelines.

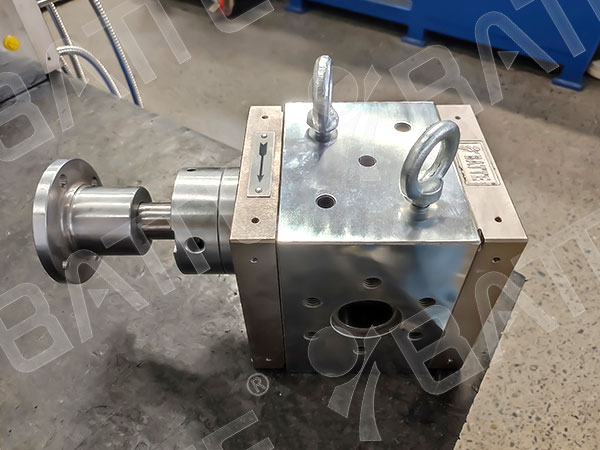

A complete hot melt adhesive delivery pump system primarily consists of a variable frequency motor, safety coupling, gear reducer, universal joint coupling, gear pump body, and reducer lubrication system. The gear pump body for hot melt adhesive transfer comprises upper and lower gear rotors, sliding bearings, sealing sleeves, and a gear pump housing. The gear rotors feature straight/helical tooth configurations, with the upper and lower gears rotating non-meshed and counter-rotating. Material is continuously drawn in at the inlet and discharged at high pressure from the outlet. The pump bearings are self-lubricated by the molten material, which returns to the pump inlet side after lubrication.

In the meshing zone of the hot melt adhesive pump gears, near the inlet, the teeth and grooves of both gears are separated, creating a low-pressure zone. Here, molten material from the extruder fills the grooves at low pressure. As the two gears rotate synchronously in opposite directions, the material is continuously conveyed toward the pump outlet within the sealed chamber formed by the gear teeth and the pump body. The teeth and grooves of the two gears enter a closed state, forcing the material out. This cycle repeats continuously to achieve material conveyance. This mechanical positive displacement conveying principle offers superior flow control performance compared to the single-screw conveying principle, which relies on solid friction and viscous drag.

Email: sale@meltpump.com

WhatsApp: +86 158 3833 1071

Any questions about our products, please feel free to contact us! We promise you high-end products and first-class service.Look forward to our cooperation!!!

- sales@battemachinery.com

- +0086-371-67991755