- Position:

- Batte Melt pump > NEWS >

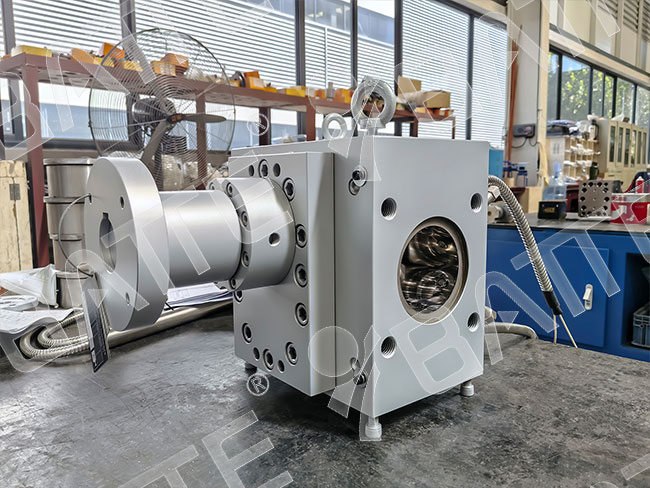

Custom melt pumps

Custom melt pumps are individually designed and manufactured to meet specific user requirements and operating conditions, finding extensive application across multiple industries including plastics, rubber, and chemical fibers.

Key customization aspects include material selection, structural design, sealing methods, and heating systems.

Material Customization: Select appropriate pump body, gear, and bearing materials based on conveyed material properties such as corrosion resistance and wear resistance. For corrosive materials, stainless steel or corrosion-resistant alloys are recommended. For high-wear applications, materials like plasma-nitrided tool steel are suitable.

Structural Customization: This includes gear tooth profiles, inlet/outlet shapes and dimensions, and mounting configurations. For instance, bell-mouth inlet/outlet designs can be adopted to eliminate dead zones in flow channels and minimize material residue. Multiple mounting options are available to accommodate varying installation spaces and drive methods, with the pump input shaft capable of horizontal or vertical orientation.

Sealing Customization: Select appropriate sealing configurations based on specific operating conditions, such as spiral seals, packing seals, or customized mechanical seal solutions to prevent melt leakage.

Heating Method Customization: For melt pumps operating at high temperatures, choose between electric heating or thermal fluid heating systems according to customer requirements to precisely control melt temperature.

Application Fields

Polymer Production: In polymerization processes for plastics, rubber, and synthetic fibers, melt pumps serve as discharge or booster pumps to convey high-temperature molten polymers like PET, PA, PS, as well as intermediates such as raw liquids, solutions, and adhesives during production.

Extrusion Molding: In extrusion production lines for plastic and rubber products—including pelletizing, film, pipe, and sheet manufacturing—melt pumps are installed between the extruder and die head. They boost and stabilize pressure, eliminating fluctuations from the extruder to deliver consistent melt pressure and flow to the die head.

Other Applications: Melt pumps are also utilized in petroleum, chemical, pharmaceutical, and food industries for conveying viscous materials like oils, fuels, lubricants, hot melt adhesives, asphalt, paints, and adhesives.

Email: sale@meltpump.com

WhatsApp: +86 158 3833 1071

Any questions about our products, please feel free to contact us! We promise you high-end products and first-class service.Look forward to our cooperation!!!

- sales@battemachinery.com

- +0086-371-67991755