- Position:

- Batte Melt pump > NEWS >

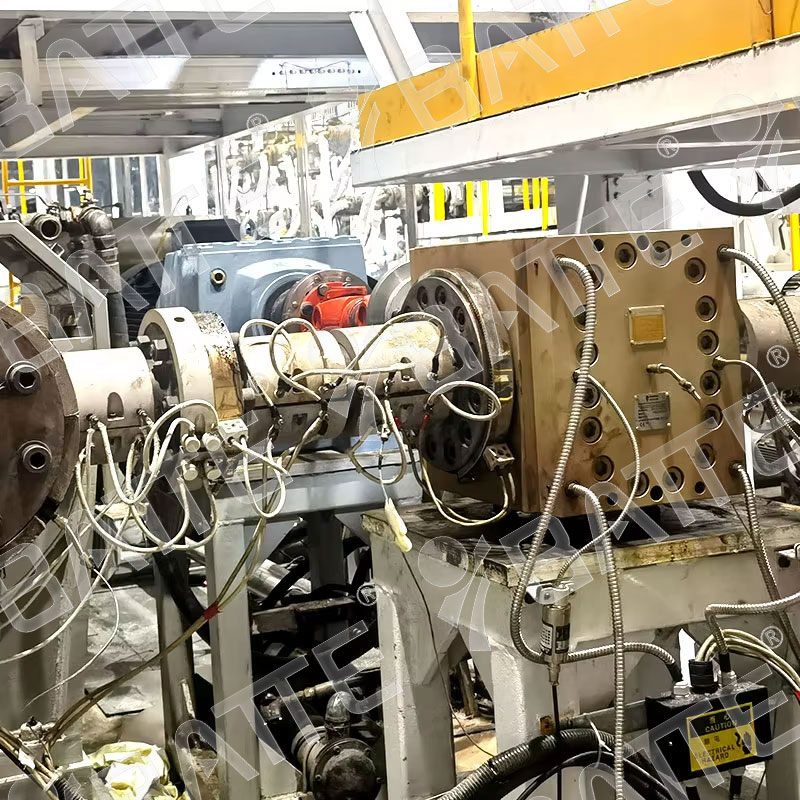

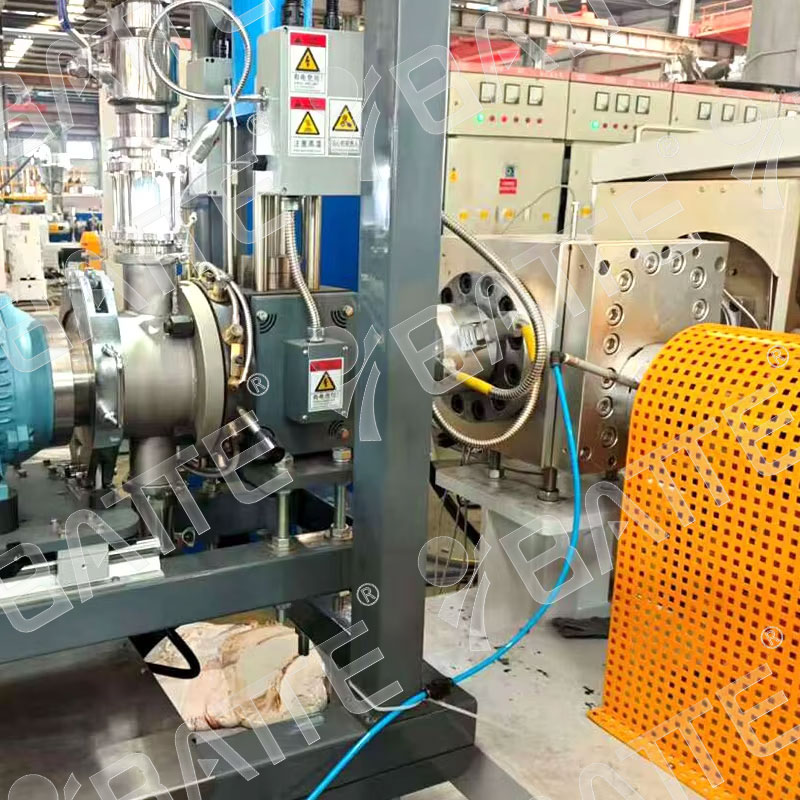

Precautions for Starting the Melt Pump

1. Tighten all screws after heating the melt pump. Operating at high temperatures causes slight deformation of the pump body and connecting components due to thermal expansion and contraction. If screws are not fully tightened, gaps may form at connections, leading to melt leakage.

2. Do not run the melt pump dry during trial operation. Only start the pump at low speed once the host machine has initiated low-speed operation and material has reached the pump inlet. Dry running causes internal components like gears and bearings to rub against each other without lubrication, accelerating wear.

3. When starting the melt pump, the rotational speed should be adjusted sequentially from 2 rpm, 5 rpm, 8 rpm, 10 rpm, 15 rpm, 20 rpm, to 25 rpm. Each speed setting must run stably for five minutes.

4. For melt pumps equipped with a cooling water ring, do not circulate cooling water during startup. Only initiate water circulation after the pump has operated normally for a period and if material leakage occurs.

Email: sale@meltpump.com

WhatsApp: +86 158 3833 1071

Any questions about our products, please feel free to contact us! We promise you high-end products and first-class service.Look forward to our cooperation!!!

- sales@battemachinery.com

- +0086-371-67991755