- Position:

- Batte Melt pump > NEWS >

Melt Pump Spiral Seal

The principle of the melt pump spiral seal is to prevent leakage of the conveyed medium outside the shaft by utilizing the counterforce generated from the multi-start spiral grooves formed within the inner bore of the seal sleeve as the gear shaft rotates.

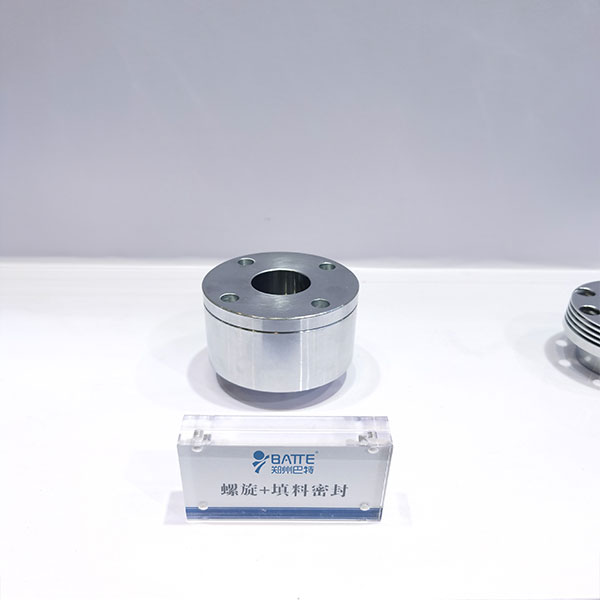

Melt Pump Screw + Packing Seal

1. Dynamic Sealing Function. The spiral seal operates as a dynamic sealing mechanism, relying on the continuous rotation of the gear shaft to maintain sealing effectiveness. As the gear shaft rotates, the multi-start spiral grooves within the seal sleeve guide the conveyed medium along a specific flow path, thereby generating a counterforce.

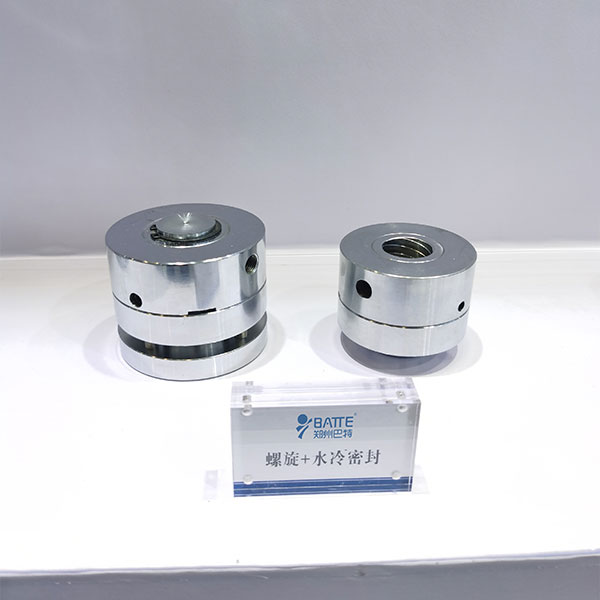

Melt Pump Screw + Water-Cooled Seal

2. The spiral groove design subjects the medium to inward pressure during flow. This pressure counteracts the medium's tendency to leak outward, creating the aforementioned counterforce. As the gear shaft continues rotating, this counterforce intensifies, effectively preventing the conveyed medium from leaking out of the shaft.

Melt Pump Screw + Air-Cooled Seal

3. Sustaining Sealing Effectiveness As long as the gear shaft remains in rotation, the helical seal continuously generates counterforce to maintain sealing performance. This dynamic sealing method exhibits self-adaptive properties, automatically adjusting sealing efficiency based on medium pressure and flow rate under varying operating conditions.

Email: sale@meltpump.com

WhatsApp: +86 158 3833 1071

Any questions about our products, please feel free to contact us! We promise you high-end products and first-class service.Look forward to our cooperation!!!

- sales@battemachinery.com

- +0086-371-67991755