- Position:

- Batte Melt pump > NEWS >

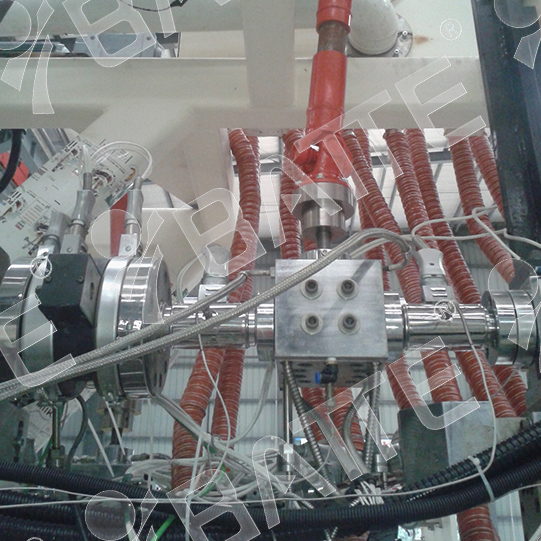

Melt pumps play a crucial role in the production of cable filler ropes

Melt pumps for cable filler ropes serve a key function in the production process of cable filler ropes, with their main roles and features as follows:

I. Roles

Pressurization and Stable Flow Conveyance:

Melt pumps can provide the necessary pressurization effect for polymer melts, ensuring the stability of the melt during conveyance and preventing fluctuations or degradation due to pressure variations or uneven temperatures.

The output flow of the melt pump is strictly proportional to its rotational speed, enabling near-linear output and providing a stable melt pressure to the cable filler rope extrusion die, ensuring a smooth extrusion process.

Enhancing Product Quality:

Melt pumps can precisely control the conveyance volume of cable filler ropes, thereby minimizing dimensional tolerances in the finished products and reducing scrap and reject rates.

Improving Production Efficiency:

Melt pumps reduce the pressure requirements on the screw, allowing the screw to extrude material at high speeds and high efficiency under lower pressure, thereby increasing the production capacity and output of the extruder.

By optimizing the extrusion process, melt pumps help reduce production cycles and improve overall production efficiency.

Energy Conservation and Emission Reduction:

Melt pumps have low energy consumption during operation, significantly reducing production costs.

Their precise metering capabilities also help reduce waste of raw materials, achieving the goal of energy conservation and emission reduction.

II. Features

Compact Structure:

Melt pumps feature a compact design, occupying a small footprint and being easy to install and maintain.

The compact structure also contributes to improved pump operating efficiency.

Strong Adaptability:

Melt pumps can withstand high temperatures and pressures, making them suitable for a variety of high-viscosity materials, such as polyethylene and polyvinyl chloride, commonly used as cable insulation and sheathing materials.

This broad applicability gives melt pumps a wide range of application prospects in the cable industry.

Excellent Adjustability:

By adjusting parameters such as the rotational speed and temperature of the melt pump, it can adapt to different production process requirements and product specifications.

Flexibly adjusting the flow, pressure, and temperature of the melt meets the needs of various cable extrusion production processes.

Dead-Zone-Free Flow Channel:

The flow channel design of melt pumps is dead-zone-free, preventing material residue and buildup within the pump.

This reduces material degradation and scorching, ensuring the stability of product quality.

Email: sale@meltpump.com

WhatsApp: +86 158 38331071

Any questions about our products, please feel free to contact us! We promise you high-end products and first-class service.Look forward to our cooperation!!!

- sales@battemachinery.com

- +0086-371-67991755