- Position:

- Batte Melt pump > NEWS >

The application scope of plastic film melt pumps

The Application Scope of Plastic Film Melt Pumps

Plastic film polymer melt pumps, also known as gear pumps, are essential components in the production of plastic films. These devices play a critical role in ensuring the efficiency, consistency, and quality of the film manufacturing process. By precisely controlling the flow and pressure of molten polymer, melt pumps are used across a wide range of applications in the plastics industry. This article explores the diverse application scope of plastic film melt pumps and their significance in various sectors.

What is a Plastic Film Melt Pump?

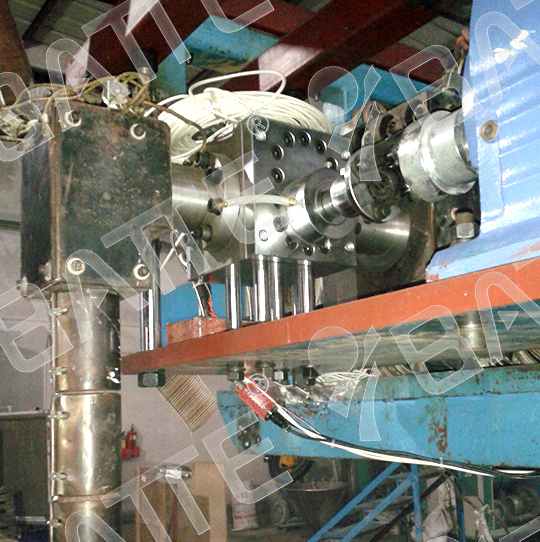

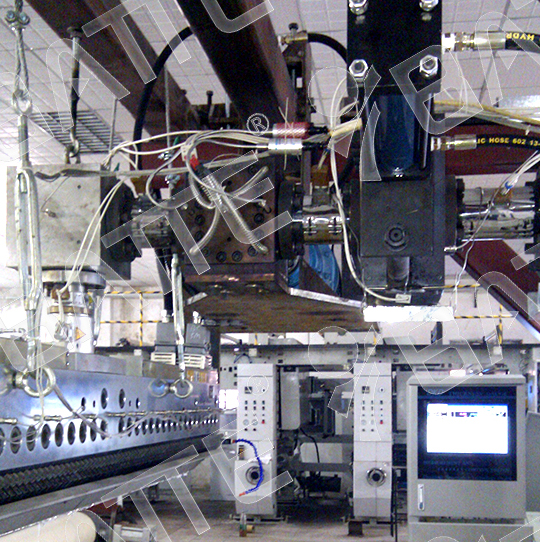

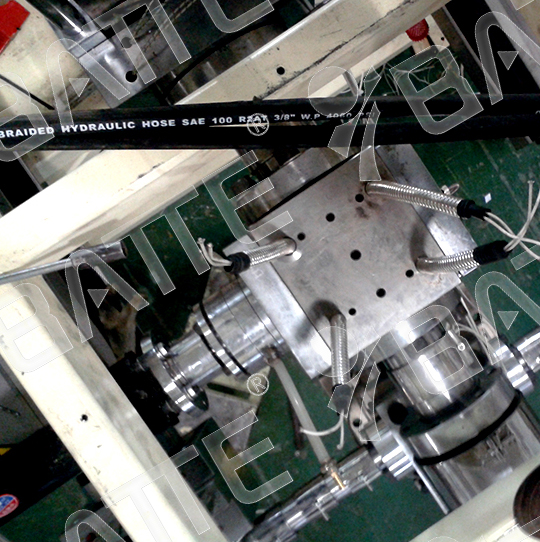

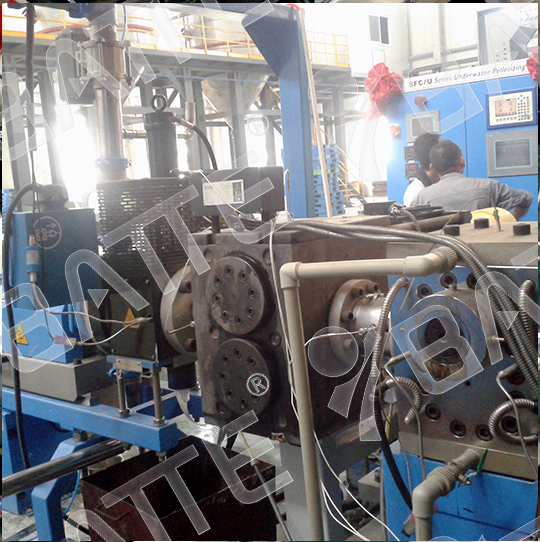

A plastic film melt pump is a positive displacement device installed between the extruder and the die in a plastic film production line. It consists of two intermeshing gears that transport molten polymer from the extruder to the die at a consistent pressure and flow rate. This process ensures uniformity in film thickness, reduces defects, and improves overall production efficiency.

Key Applications of Plastic Film Melt Pumps

The versatility and precision of melt pumps make them suitable for a wide range of plastic film production processes. Below are some of the key application areas:

1. Packaging Films

Packaging films are one of the most common applications of melt pumps. These films are used in various industries, including food, beverage, and consumer goods. Melt pumps ensure the production of high-quality films with consistent thickness and surface finish, which are critical for:

Food Packaging: Films used for wrapping, sealing, and preserving food products.

Stretch Films: Films used for pallet wrapping and securing goods during transportation.

Shrink Films: Films that shrink when heated, commonly used for packaging bottles, cans, and other products.

2. Agricultural Films

Melt pumps are widely used in the production of agricultural films, which play a vital role in modern farming practices. These films are designed to enhance crop yield, conserve water, and protect plants. Key applications include:

Mulch Films: Used to cover soil, retain moisture, and control weed growth.

Greenhouse Films: Provide insulation and UV protection for greenhouse structures.

Silage Films: Used to wrap and preserve animal fodder.

3. Industrial Films

Industrial films require high strength, durability, and precision, making melt pumps indispensable in their production. Applications include:

Protective Films: Used to safeguard surfaces during manufacturing, transportation, and storage.

Barrier Films: Films with high resistance to gases, moisture, and chemicals, used in sensitive industrial applications.

Laminating Films: Films used to bond multiple layers of materials for enhanced performance.

4. Medical Films

In the medical industry, melt pumps are used to produce films that meet stringent quality and safety standards. These films are used in:

Medical Packaging: Sterile films for packaging medical devices, instruments, and pharmaceuticals.

Diagnostic Films: Films used in diagnostic equipment and testing kits.

Surgical Films: Films used in surgical procedures and wound care.

5. Specialty Films

Melt pumps are also used in the production of specialty films, which require unique properties and high precision. Examples include:

Optical Films: Films used in displays, screens, and lighting applications.

Conductive Films: Films with electrical conductivity, used in electronics and sensors.

Biodegradable Films: Eco-friendly films designed to decompose after use, reducing environmental impact.

Benefits of Melt Pumps in Plastic Film Production

The widespread use of melt pumps in plastic film production is driven by their numerous advantages:

Consistent Film Quality: Melt pumps ensure uniform thickness and reduce defects, resulting in high-quality films.

Increased Production Efficiency: By stabilizing pressure and flow, melt pumps enable higher production speeds and reduced downtime.

Energy Savings: Melt pumps reduce the load on extruders, leading to lower energy consumption.

Material Savings: Precise control minimizes material waste, making the process more cost-effective.

Versatility: Melt pumps can handle a wide range of polymers, including polyethylene (PE), polypropylene (PP), and polyethylene terephthalate (PET).

Emerging Trends and Future Applications

As the plastics industry evolves, melt pumps are being adapted to meet new challenges and opportunities. Some emerging trends include:

Sustainable Films: The growing demand for biodegradable and recyclable films is driving the development of melt pumps capable of processing eco-friendly materials.

High-Performance Films: Advances in polymer technology are enabling the production of films with enhanced properties, such as higher strength, flexibility, and barrier performance.

Smart Films: The integration of sensors and functional additives into films is opening up new applications in electronics, healthcare, and packaging.

Plastic film melt pumps are indispensable tools in the production of a wide range of films, from everyday packaging materials to advanced specialty films. Their ability to deliver precise control, consistency, and efficiency makes them a cornerstone of modern plastic film manufacturing. As the demand for high-quality, sustainable, and innovative films continues to grow, the application scope of melt pumps will expand, further solidifying their role in the plastics industry. Whether in packaging, agriculture, healthcare, or industrial applications, melt pumps are driving progress and enabling the production of films that meet the needs of a rapidly changing world.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071

Any questions about our products, please feel free to contact us! We promise you high-end products and first-class service.Look forward to our cooperation!!!

- sales@battemachinery.com

- +0086-371-67991755