- Position:

- Batte Melt pump > NEWS >

application scope of plastic film extruder melt pump

Plastic Film Extruder Melt Pump: Expanding Its Application Scope

In the rapidly evolving plastics industry, the plastic film extruder melt pump has emerged as a crucial component in the production process. Traditionally, melt pumps have been utilized primarily in the extrusion of plastic films, ensuring a consistent and steady flow of molten plastic material. However, with technological advancements and increasing demand for precision in plastic processing, the application scope of the plastic film extruder melt pump is broadening significantly.

Original Applications in Plastic Film Extrusion

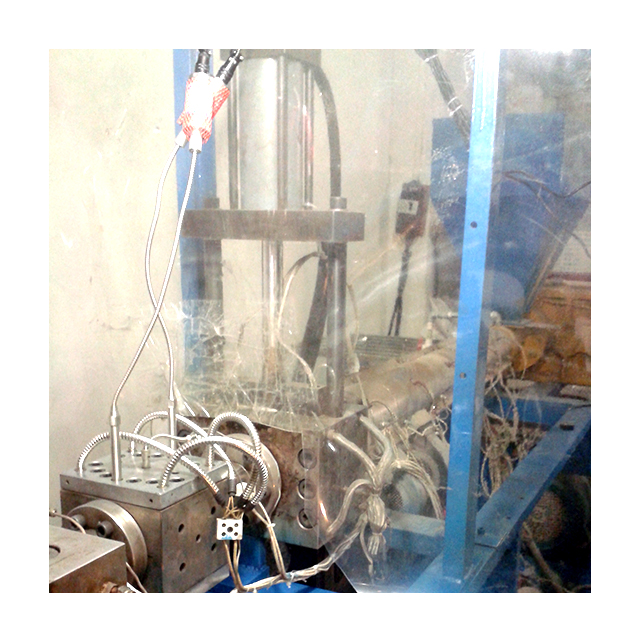

The plastic film extruder melt pump has been a staple in the production of various types of plastic films, including packaging films, agricultural films, and industrial films. By maintaining a constant pressure and flow rate, the melt pump helps to produce films with uniform thickness and improved surface quality. This consistency is essential for applications that require high-performance films, such as those used in food packaging, where barrier properties and mechanical strength are critical.

Expanding into Other Extrusion Processes

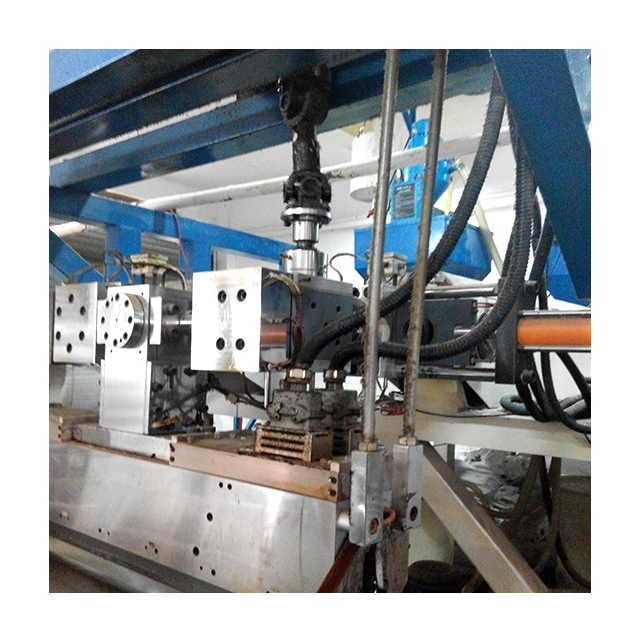

Beyond plastic films, the melt pump is now being adopted in other extrusion processes, such as the production of pipes, profiles, and sheets. In these applications, the melt pump provides similar benefits by ensuring a stable and controlled flow of molten plastic material. This stability is particularly important in the production of large-diameter pipes and thick sheets, where inconsistencies in the material flow can lead to defects and reduce product quality.

Innovative Uses in Compounding and Recycling

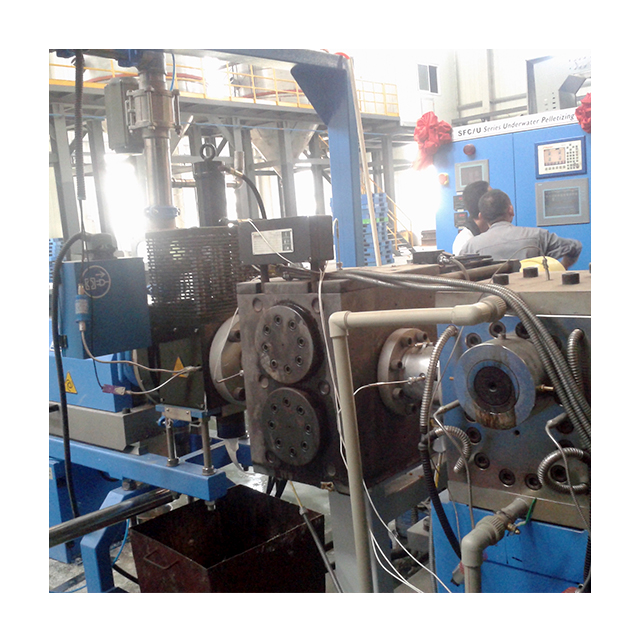

The plastic film extruder melt pump is also finding innovative uses in the compounding and recycling of plastics. In compounding, the melt pump can help to blend different types of plastics and additives more uniformly, resulting in improved product performance. In recycling processes, the melt pump can handle contaminated and degraded plastics more effectively, enabling the production of high-quality recycled materials.

Potential for Future Developments

As the plastics industry continues to evolve, the plastic film extruder melt pump is poised for further expansion into new application areas. With ongoing research and development, the pump's design and functionality can be optimized to meet the specific needs of emerging technologies and markets. For example, the melt pump could play a critical role in the development of advanced materials, such as biodegradable plastics and nanocomposites, which require precise control over the extrusion process.

In summary, the plastic film extruder melt pump has traditionally been used in the production of plastic films, but its application scope is rapidly expanding. With its ability to provide a consistent and steady flow of molten plastic material, the melt pump is now being adopted in other extrusion processes, compounding, and recycling. As the plastics industry continues to innovate and grow, the melt pump will likely play an increasingly important role in shaping the future of plastic processing.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071

Any questions about our products, please feel free to contact us! We promise you high-end products and first-class service.Look forward to our cooperation!!!

- sales@battemachinery.com

- +0086-371-67991755