- Position:

- Batte Melt pump > NEWS >

Operating temperature and working pressure of polymer melt gear pumps

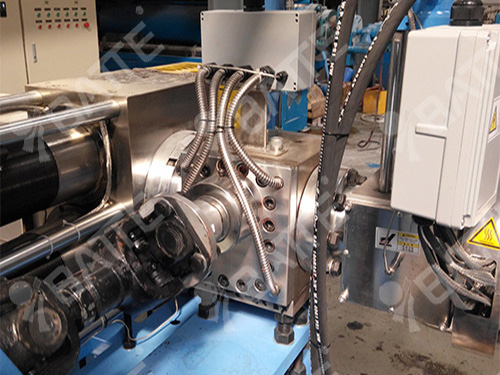

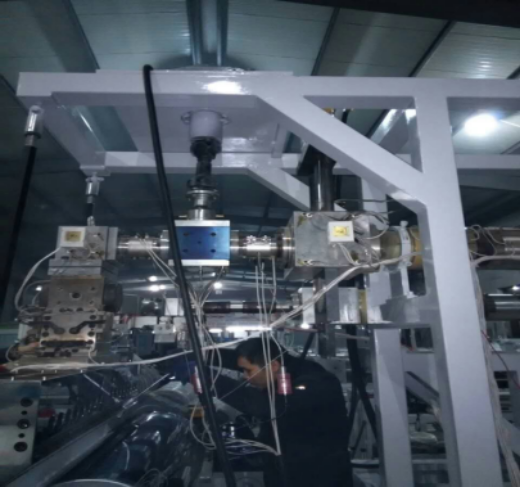

The operating temperature of polymer melt gear pumps can generally reach 300°C, meeting the requirements of most plastic melt conveying processes. Some melt pumps made of high-temperature-resistant materials can withstand temperatures up to 500°C. Melt gear pumps are primarily used for conveying, pressurizing, and metering high-temperature, high-viscosity polymer melts. They are widely applied in the extrusion molding of plastics, resins, rubbers, and chemical fiber products.

The working pressure of melt gear pumps is usually represented by three parameters: inlet pressure, outlet pressure, and pressure difference. Ordinary melt gear pumps have an inlet pressure less than 10 MPa, an outlet pressure less than 35 MPa, and a pressure difference of up to 25 MPa. For high-pressure-resistant melt gear pumps, the outlet pressure can reach 50 MPa.

The inlet pressure of a melt gear pump does not need to be excessively high, generally ranging from 3 to 5 MPa. Higher inlet pressures are required for high-viscosity fluids. Sometimes, to enhance the mixing of the melt within the extruder screw, a higher pressure is needed at the screw head to increase backflow, and the inlet pressure can be adjusted upwards in such cases. The inlet pressure can be adjusted by regulating the upstream equipment (such as the extruder). The outlet pressure of a melt gear pump depends on factors such as die shape, melt viscosity, and flow rate.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071

Any questions about our products, please feel free to contact us! We promise you high-end products and first-class service.Look forward to our cooperation!!!

- sales@battemachinery.com

- +0086-371-67991755