- Position:

- Batte Melt pump > NEWS >

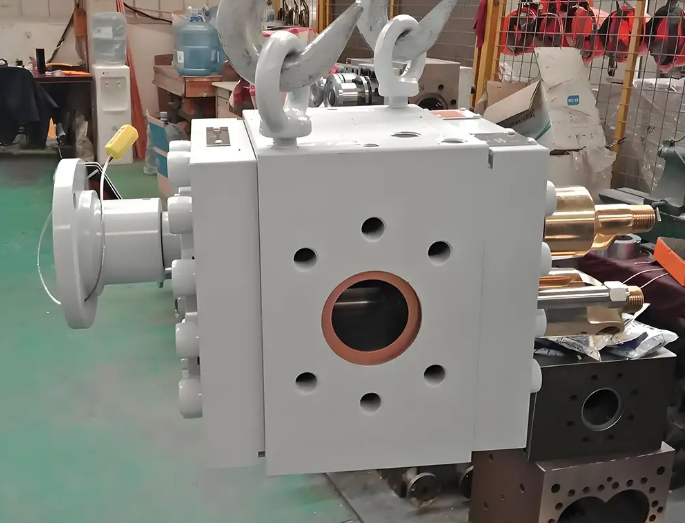

Rubber extruder gear pump

In the field of rubber and elastomer processing, rubber extruder gear pumps play an extremely important role. As a key equipment connecting the outlet of the extruder and the die head, it plays a decisive role in the precise measurement and stable transportation of the melt, directly affecting the quality and production efficiency of the final rubber products.

The gear pump of rubber extruder is mainly composed of core components such as pump body, gear, shaft, and sealing device. The pump body provides a solid shell support for the entire gear pump, ensuring the stable operation of internal components. Gears are the core working components, usually using specially designed tooth profiles and high-precision machining processes to ensure the meshing accuracy between gears and achieve precise measurement and stable pushing of rubber melt. The shaft bears the responsibility of transmitting power, transferring the torque of the external driving device to the gears, enabling them to operate continuously. The sealing device is crucial as it can effectively prevent the leakage of rubber melt under high pressure, ensuring the normal operation of equipment and the safety and cleanliness of the working environment. In addition, its unique built-in cooling channel design is a major highlight. The cooling channels are distributed in key parts of the pump body, absorbing and removing the heat generated by the gear pump during operation through circulating coolant, thereby achieving precise temperature control and avoiding problems such as degradation or performance deterioration of rubber melt due to high temperature.

High precision measurement: With precision designed and manufactured gears, the rubber melt gear pump can accurately control the conveying volume of rubber melt with minimal error, providing reliable guarantee for the standardized production of rubber products. For example, in the production of high-precision rubber seals, accurate melt measurement can ensure the dimensional accuracy and performance consistency of the seals.

Accurate and fast temperature control: The built-in cooling channel allows for more precise and rapid temperature control. In the rubber processing, different rubber formulas and processes have strict temperature requirements. This gear pump can respond to temperature changes in a timely manner. By adjusting the flow rate and temperature of the cooling medium, the melt temperature is stabilized within the ideal range, effectively improving the stability of product quality.

Special lubrication channel design: Based on the characteristics of rubber and elastic materials, specially designed lubrication channels can ensure the normal operation of gears in high viscosity and corrosive rubber melt environments, reduce wear, extend the service life of gear pumps, and reduce equipment maintenance costs.

Channel optimization reduces residue: By optimizing the design of the channel, dead corners inside the channel are eliminated. During the transportation of rubber melt, dead corners can easily lead to polymer residue, which not only affects product quality but may also cause production interruptions. And this gear pump effectively reduces polymer residue, improves the purity and quality stability of the product, for example, when producing high-quality rubber pipes, it can avoid impurities and defects on the inner wall of the pipe.

Stable output pressure: The improved gear parameter design enables the gear pump to have more accurate rotational displacement and output stable pressure. Stable pressure is crucial for ensuring the shape, dimensional accuracy, and physical properties of rubber products under precision extrusion conditions. For example, in the molding process of rubber tires, stable pressure can ensure uniform thickness of the rubber layer in various parts of the tire, improving the balance and safety of the tire.

Rubber extruder gear pumps are widely used in the production of numerous rubber and elastomer products. In the field of automotive rubber component manufacturing, such as production lines for tires, seals, shock absorbers, etc., it can accurately measure and stably transport rubber melt, ensuring product quality and production efficiency. It is also indispensable in the extrusion processing of rubber products such as rubber pipes, tapes, and rubber sheets, which can achieve high-quality and high-precision continuous production. In addition, in some special rubber products, such as medical rubber products, electronic rubber accessories, and other fields that require high quality, rubber melt gear pumps play a key role with their advantages, helping enterprises produce products that meet strict standards and meet the market's demand for high-quality rubber products.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071

Any questions about our products, please feel free to contact us! We promise you high-end products and first-class service.Look forward to our cooperation!!!

- sales@battemachinery.com

- +0086-371-67991755