- Position:

- Batte Melt pump > NEWS >

Does the rotational speed of the melt pump have any effect on the melt flow rate?

The rotational speed of the extruder melt pump has a direct and significant impact on the melt flow rate. The following is a detailed analysis of this impact:

Direct Proportionality

The flow rate of the melt pump exhibits a strict direct proportionality with its rotational speed. This means that as the rotational speed of the melt pump increases, the conveyed melt flow rate correspondingly increases; conversely, when the rotational speed decreases, the melt flow rate also decreases. This characteristic makes adjusting the rotational speed of the melt pump an effective means of controlling the melt flow rate.

Flow Stability

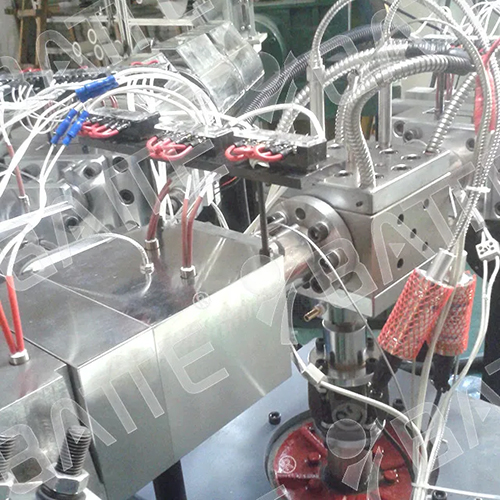

The melt pump employs a positive displacement principle, using two intermeshing gears (or other forms of rotors) rotating within the pump body to create a varying working volume to convey the melt. This mode of conveyance enables the melt pump to maintain a high degree of flow rate stability during transport, with minimal influence from factors such as melt viscosity and pressure. Consequently, even at different rotational speeds, the melt pump ensures consistent and accurate melt flow rates.

Precise Control

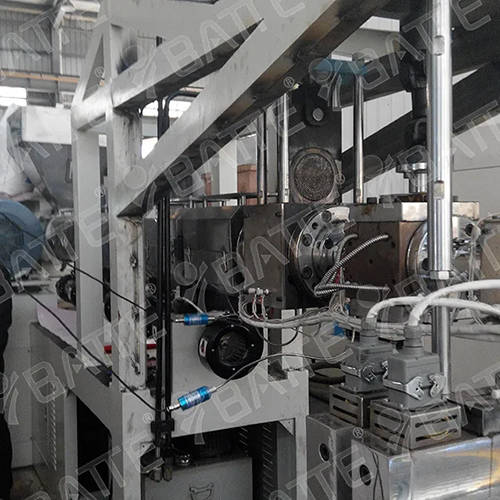

To achieve precise control of the melt flow rate, a PLC control system is typically integrated with the melt pump. This control system enables real-time monitoring and adjustment of the pump's rotational speed, thereby facilitating precise regulation of the melt flow rate. This is particularly crucial for production processes requiring high-precision flow control.

Practical Application

In practical applications, the rotational speed range of the melt pump varies according to different production requirements and melt characteristics. For instance, when conveying high-temperature melts, the operational rotational speed range of the melt pump typically falls between 10 and 100 revolutions per minute, with the specific speed depending on the actual operating conditions of the production process. By adjusting the rotational speed within this range, precise control of the melt flow rate can be achieved to meet various production demands.

Comprehensive Effects

Beyond its direct influence on the melt flow rate, the rotational speed of the melt pump can also have comprehensive effects on product quality, extrusion process stability, production output, and efficiency. For example, increasing the rotational speed of the melt pump can enhance the injection pressure, contributing to improved filling rates for products with complex microstructures. Additionally, by regulating the rotational speed to stabilize melt pressure and flow rate, fluctuations during the extrusion process can be reduced, ensuring stability and consistency throughout the process.

In summary, the rotational speed of the melt pump has a direct and significant impact on the melt flow rate. By rationally adjusting the rotational speed of the melt pump, precise control of the melt flow rate can be achieved, satisfying diverse production requirements while ensuring process stability and product quality.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071

Any questions about our products, please feel free to contact us! We promise you high-end products and first-class service.Look forward to our cooperation!!!

- sales@battemachinery.com

- +0086-371-67991755