- Position:

- Batte Melt pump > NEWS >

Does the sheet extrusion production line need to use a melt pump?

The question of whether a extrusion gear pump is absolutely necessary for a sheet extrusion line does not have a definitive answer. It primarily depends on specific production needs, process conditions, and economic benefits, among other factors. Below is a detailed analysis of this issue:

I. Role of Melt Pump in Sheet Extrusion Lines

Stable Extrusion: The melt pump eliminates feeding errors from the feeding system and mitigates fluctuations transmitted from upstream processes, resulting in a more stable extrusion process. This enhances the dimensional accuracy of the sheets and reduces waste rates.

Increased Production and Reduced Energy Consumption: The melt pump establishes die pressure more efficiently, reduces backpressure on the extruder, and decreases the axial force on the screw, thereby prolonging equipment life. Additionally, it enables low-temperature extrusion, which boosts production while lowering energy consumption.

Facilitates Coordination between Upstream and Downstream Equipment: The melt pump exhibits linear extrusion characteristics, with its delivery capacity essentially linear to its rotational speed, simplifying the coordination between upstream and downstream equipment.

II. Analysis of the Necessity of Using Melt Pumps

Production Requirements: If the sheet extrusion line demands high precision in product dimensions, surface quality, or involves expensive raw materials, the use of a melt pump can significantly improve product quality and reduce waste. In such cases, the employment of a melt pump is crucial.

Process Conditions: Under certain specific process conditions, such as the need for low-temperature extrusion, high output, or low energy consumption, the melt pump becomes an indispensable component.

Economic Benefits: Although the initial investment in a melt pump is substantial, its long-term benefits, including improved product quality, increased production, and reduced energy consumption, can offset or even surpass the initial costs. Therefore, economic analysis is necessary when considering the adoption of a melt pump.

III. Conclusion

In conclusion, the necessity of a melt pump in sheet extrusion lines is situation-dependent. When conditions permit, using a melt pump can significantly enhance production efficiency and product quality. However, if the production line has low requirements for product quality and output, or if the initial investment cost is prohibitively high, resulting in unfavorable economic benefits, forgoing the melt pump may be a viable option. Hence, enterprises should comprehensively consider their actual circumstances and weigh the pros and cons when deciding on the use of a melt pump.

IV. Other Considerations

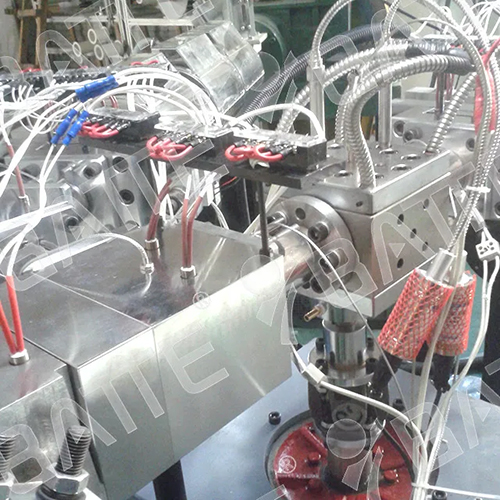

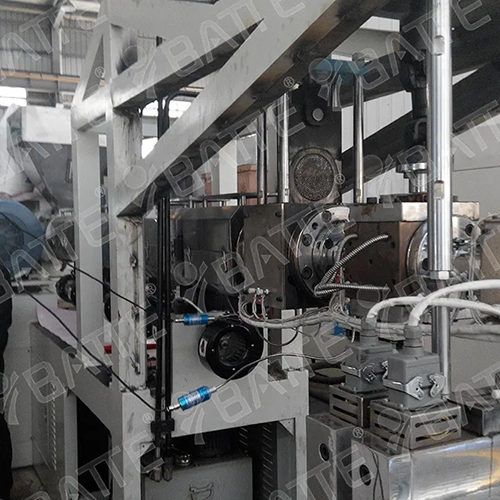

Selection and Configuration: When selecting a melt pump, factors such as the specific needs of the production line, process conditions, and material properties should be taken into account for proper selection and configuration.

Operation and Maintenance: Regular maintenance and servicing of the polymer melt pump are essential to ensure its smooth operation and extended lifespan. Operators must also be trained in proper operating procedures and precautions.

Safety and Environmental Protection: When using a melt pump, attention must be paid to safety and environmental protection. Ensure that the equipment complies with relevant safety standards and environmental requirements to prevent accidents and pollution.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071

Any questions about our products, please feel free to contact us! We promise you high-end products and first-class service.Look forward to our cooperation!!!

- sales@battemachinery.com

- +0086-371-67991755