- Position:

- Batte Melt pump > NEWS >

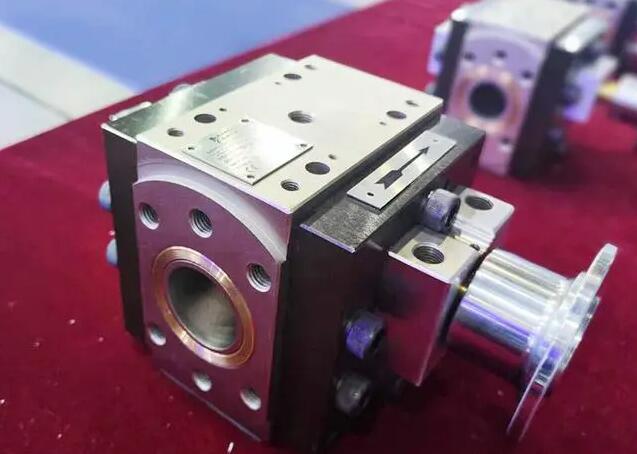

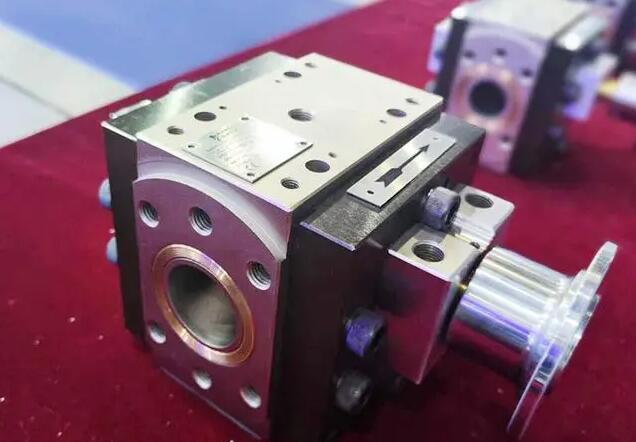

Explanation of the Working Principle of Spiral Seals in Melt Pumps

The working principle of the spiral seal of the melt pump mainly involves the dynamic sealing mechanism, and its core is to use the reverse thrust formed by the multi head spiral groove in the inner hole of the sealing sleeve during the operation of the gear shaft to prevent the leakage of the conveying medium to the outside of the shaft, thereby achieving the sealing effect. The following is a detailed explanation of the working principle:

Detailed explanation of working principle

1. Dynamic sealing function:

Spiral seal is a dynamic sealing method that relies on the continuous rotation of the gear shaft to maintain the sealing effect. When the gear shaft rotates, the multi head spiral groove inside the sealing sleeve will guide the conveying medium to flow along a specific path, thereby forming a counter thrust.

2. Formation of Counterthrust:

The design of the spiral groove causes the medium to experience inward pressure during the flow process, which counteracts the tendency of the medium to leak outward, forming a so-called reverse thrust. As the gear shaft continues to rotate, the thrust increases, effectively preventing the leakage of the conveying medium outside the shaft.

3. Maintenance of sealing effect:

As long as the gear shaft remains in a rotating state, the spiral seal can continuously generate thrust and maintain its sealing effect. This dynamic sealing method has adaptability and can automatically adjust the sealing performance according to the pressure and flow rate of the medium under different working conditions.

Applicability and Precautions

1. Applicability:

Spiral seals are particularly suitable for high viscosity melts and dynamic sealing applications with positive inlet pressure. In melt pumps, it is often used to prevent leakage of high-temperature and high viscosity polymer melts.

2. Attention:

For low viscosity polymers (such as PP, PE, and PS) transported by the melt pump, it is recommended to install a cooling jacket (or cold water plate) at the shaft end to increase the viscosity of the melt medium and achieve better sealing effect. In addition, the sealing effect of spiral seals is also affected by the design parameters of the spiral groove (such as groove depth, groove width, spiral angle, etc.) and the properties of the medium (such as viscosity, temperature, pressure, etc.). Therefore, in practical applications, it is necessary to choose and adjust according to specific situations.

The working principle of the spiral seal of the melt pump is to prevent the leakage of the conveying medium to the outside of the shaft by the reverse thrust formed by the multi head spiral groove in the inner hole of the sealing sleeve when the gear shaft rotates. This sealing method has the characteristics of dynamic adaptability, self sealing, and good sealing effect, and has been widely used in high-temperature and high viscosity polymer melt conveying equipment such as melt pumps for extrusion.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071

Any questions about our products, please feel free to contact us! We promise you high-end products and first-class service.Look forward to our cooperation!!!

- sales@battemachinery.com

- +0086-371-67991755