- Position:

- Batte Melt pump > NEWS >

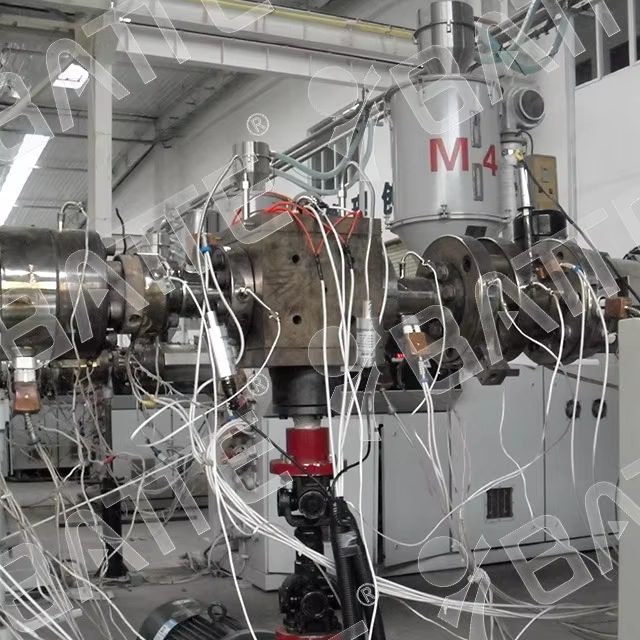

Structure and Self-Lubrication Principle of Bushings for Melt Metering Gear Pumps

The structural design of bushings for melt metering gear pumps allows the melt to easily penetrate the clearance between the hole and the shaft, achieving effective self-lubrication. These bushings are characterized by the following features: within the inner bore wall of the bushing, there are melt infiltration grooves designed to direct the flow. Additionally, reflux grooves are incorporated on one side wall and the outer side wall of the bushing. The melt infiltration grooves feature a larger opening towards the melt pump chamber side, which is deeper and wider compared to the smaller opening near the cover plate side. The grooves extend from the larger end to the smaller end with a certain degree of curvature, gradually tapering from a deeper, wider opening to a shallower, narrower one. The reflux grooves, on the other hand, are positioned adjacent to but not intersecting with the smaller ends of the infiltration grooves, extending from one side wall of the bushing to its outer side wall.

The bushings for melt metering gear pumps are symmetrically arranged, each corresponding to the drive shaft and the driven shaft respectively. The reflux grooves of the two bushings are aligned to form reflux holes. When these bushings are installed on the drive and driven shafts of the pump body, they rotate relative to the shafts. A small portion of the melt within the pump body infiltrates into the inner bore wall of the bushings through the larger ends of the infiltration grooves, providing excellent lubrication. The melt then flows out from the smaller ends of the infiltration grooves into the adjacent reflux grooves. Under the action of pressure differential inside and outside the pump, this self-lubricating melt is recirculated back into the pump chamber, completing a self-lubrication cycle. This mechanism reduces wear between the bushings and shafts, ensuring long-term stable operation of the melt metering gear pump.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071

Any questions about our products, please feel free to contact us! We promise you high-end products and first-class service.Look forward to our cooperation!!!

- sales@battemachinery.com

- +0086-371-67991755