- Position:

- Batte Melt pump > NEWS >

What are the materials of polypropylene conveyor gear metering pumps?

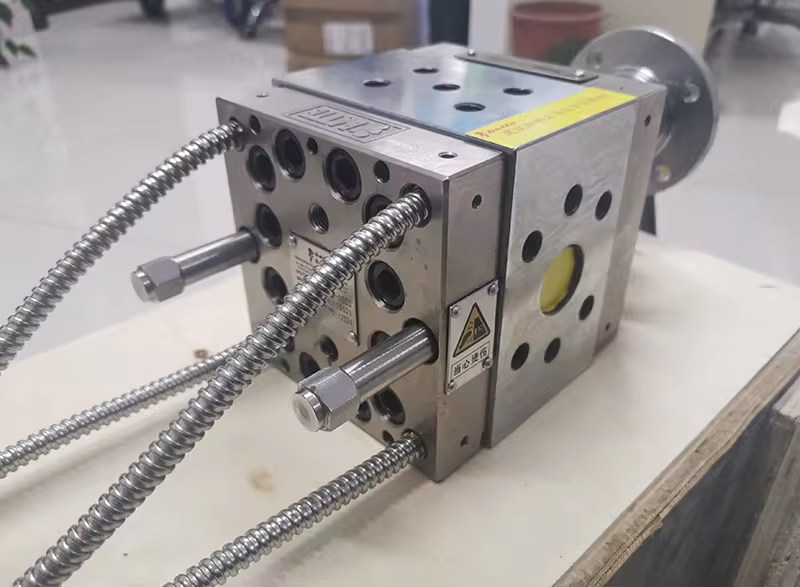

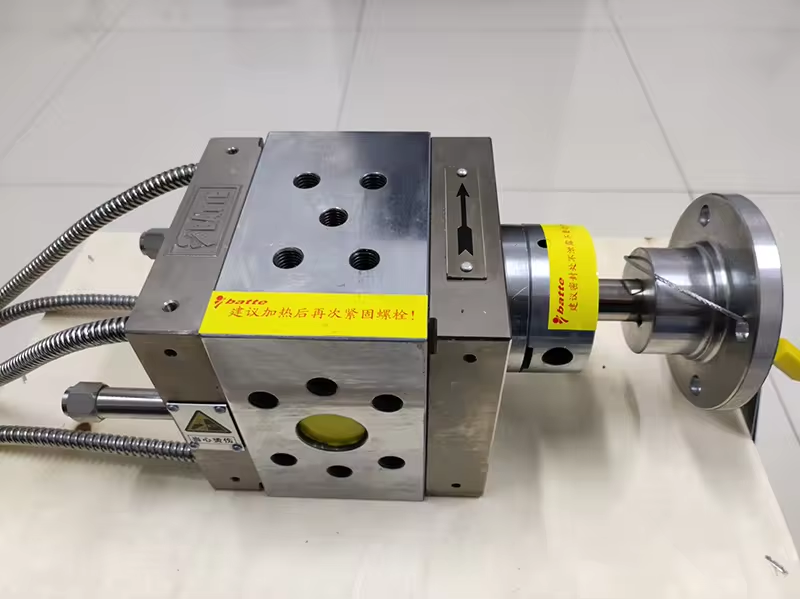

The polypropylene conveying gear metering pump, as a key equipment in industrial fields such as chemical fiber and textile, its performance and service life are directly affected by the manufacturing materials. Choosing appropriate materials is of great significance for ensuring the stable operation of gear metering pumps, improving conveying efficiency, and extending their service life. This article will provide a detailed analysis of the main materials used in polypropylene fiber conveying gear metering pumps, including the material selection and characteristics of pump bodies, gears, shaft sleeves, sealing devices, and other components.

1、 Material of pump body

The pump body is the main part of the polypropylene conveying gear metering pump, which bears the pressure and friction generated by the internal gear rotation. Therefore, the pump body material needs to have excellent wear resistance, corrosion resistance, and certain strength. Common pump body materials include cast iron, cast steel, stainless steel, etc.

Cast iron: Cast iron has good casting and mechanical properties, and the cost is relatively low. However, its corrosion resistance is relatively weak, making it suitable for situations with low requirements for corrosion.

Cast steel: Cast steel has high strength and toughness, suitable for high-pressure and high load working conditions. The pump body made of cast steel material can withstand large internal pressure, ensuring the stable operation of the gear metering pump.

Stainless steel: Stainless steel has excellent corrosion resistance and is suitable for conveying corrosive media. The surface of the stainless steel pump body is smooth, easy to clean and maintain, and can ensure the purity of the conveying medium.

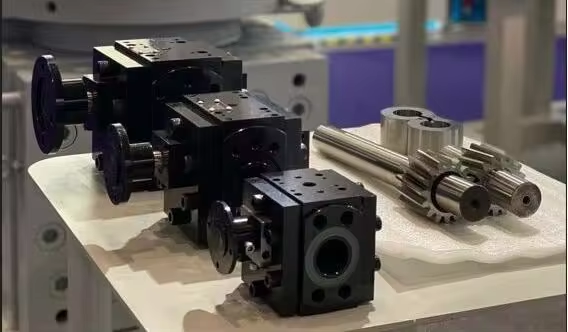

2、 Gear material

The gear is the core component of the polypropylene fiber conveying gear metering pump, and its material selection directly affects the conveying efficiency and service life of the pump. Common gear materials include carbon steel, stainless steel, alloy steel, etc.

Carbon steel: Carbon steel gears have high strength and hardness, suitable for conveying tasks under general working conditions. However, its corrosion resistance is relatively weak, and attention should be paid to the corrosive effect of the medium on the gears.

Stainless steel: Stainless steel gears have excellent corrosion resistance and are suitable for conveying corrosive media. Stainless steel gears have a smooth surface and low friction coefficient, which can reduce energy consumption and improve conveying efficiency.

Alloy steel: Alloy steel gears combine the advantages of high strength and corrosion resistance, making them suitable for high-pressure and highly corrosive working conditions. Alloy steel gears can withstand large loads and impacts, ensuring the stable operation of gear metering pumps.

3、 Material of shaft sleeve

The shaft sleeve of the pump can protect the connection between the pump rotor and the pump casing from wear. The higher the speed of the pump, the greater its wear and heat generation, and the more obvious the effect of the shaft sleeve. Common shaft materials include carbon steel, alloy steel, etc.

Carbon steel: Carbon steel shafts have high strength and stiffness, suitable for power transmission under general working conditions. However, its corrosion resistance is relatively weak, and attention should be paid to the corrosive effect of the medium on the shaft.

Alloy steel: Alloy steel shafts combine the advantages of high strength and corrosion resistance, making them suitable for high-pressure and highly corrosive working conditions. The alloy steel shaft can withstand large torque and bending forces, ensuring the stable operation of the gear metering pump.

4、 Sealing device material

The sealing device is a key component of the polypropylene conveying gear metering pump, used to prevent internal and external leakage of the pump body. Therefore, the material of the sealing device needs to have excellent sealing performance and wear resistance. Common sealing device materials include rubber, polytetrafluoroethylene (PTFE), etc.

Rubber: Rubber seals have good elasticity and sealing performance, suitable for sealing needs under general working conditions. However, its high temperature and corrosion resistance are relatively weak, and attention should be paid to the limitations of the usage environment.

Polytetrafluoroethylene (PTFE): PTFE seals have excellent corrosion resistance and high temperature resistance, suitable for conveying corrosive and high-temperature media. PTFE seals have a smooth surface and low friction coefficient, which can reduce the risk of leakage and improve the sealing effect.

5、 Material selection and optimization suggestions

When selecting the material for the polypropylene conveying gear metering pump, it is necessary to comprehensively consider factors such as working conditions, medium properties, service life, and cost. Here are some suggestions:

Select materials with good corrosion resistance based on the properties of the conveying medium to ensure the long-term stable operation of the pump body.

Choose materials with high strength and toughness based on work pressure and load conditions to withstand internal pressure and external impacts.

Priority should be given to using materials with good wear resistance to extend the service life of gear metering pumps and reduce maintenance costs.

On the premise of meeting performance requirements, try to choose materials with lower costs to reduce equipment investment costs.

The material selection of polypropylene conveying gear metering pump is of great significance for ensuring the performance and service life of the pump. By selecting materials such as pump body, gears, shaft, and sealing device reasonably, the advantages of gear metering pumps can be fully utilized, transportation efficiency can be improved, and operating costs can be reduced. In practical applications, it is necessary to optimize material selection based on specific operating conditions and medium properties to achieve optimal performance and economic benefits.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071

Any questions about our products, please feel free to contact us! We promise you high-end products and first-class service.Look forward to our cooperation!!!

- sales@battemachinery.com

- +0086-371-67991755