- Position:

- Batte Melt pump > NEWS >

Explanation of the application working conditions of the melt gear pump

The working temperature of the melt gear pump: ≤ 350-400 ℃, cleaning temperature: ≤ 450 ℃, outlet pressure: ≤ 350bar, viscosity: ≤ 30000Pa. s. The sealing of melt gear pumps generally adopts spiral sealing, which has good wear resistance. Drive motor+reducer+universal coupling+pump body. The motor adopts variable frequency speed regulation or servo speed regulation, and can be adjusted to the required flow rate at will. For products with high precision requirements, it is recommended to use servo motor speed regulation.

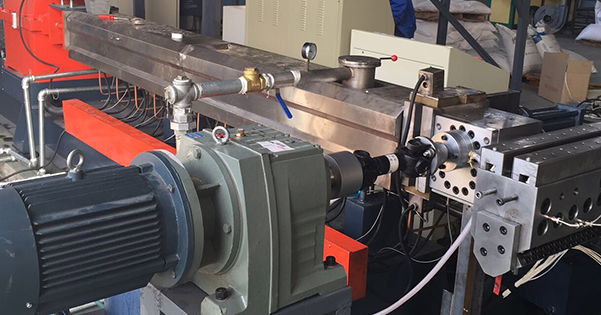

melt gear pump

The working temperature of the melt gear pump: ≤ 350-400 ℃, cleaning temperature: ≤ 450 ℃, outlet pressure: ≤ 350bar, viscosity: ≤ 30000Pa. s. The sealing of melt gear pumps generally adopts spiral sealing, which has good wear resistance. Drive motor+reducer+universal coupling+pump body. The motor adopts variable frequency speed regulation or servo speed regulation, and can be adjusted to the required flow rate at will. For products with high precision requirements, it is recommended to use servo motor speed regulation.

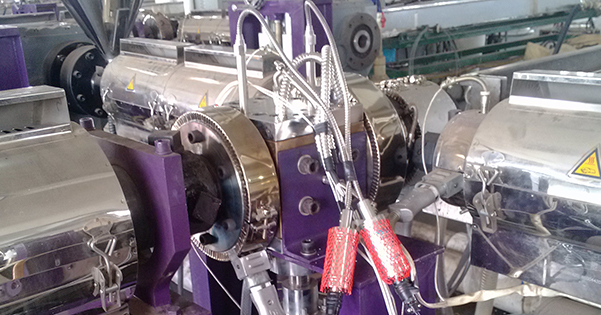

polymer melt pump

The heating of the melt gear pump uses an electric heating rod to accurately control the melt temperature. The melt gear pump belongs to the positive displacement gear pump, which uses a cylindrical gear (helical gear) that is engaged externally to rotate relative to each other to transport high viscosity fluids. All gears and mating surfaces are finely ground and assembly clearances are strictly controlled to obtain accurate flow.

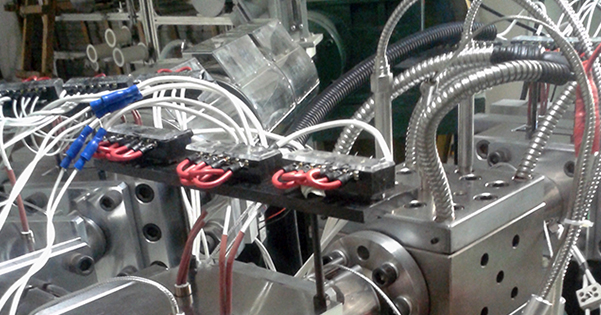

melt pump in extruder

The polymer melt pump body is equipped with unloading ports to strictly control the fluctuation of system output pressure.

The system is equipped with end bearing flushing holes to ensure long-term durability of the bearings.

The melt gear pump body cavity of the melt gear pump is designed using high-temperature fluid dynamics to ensure feeding and discharging under large working conditions and improve product meshing performance.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071

Any questions about our products, please feel free to contact us! We promise you high-end products and first-class service.Look forward to our cooperation!!!

- sales@battemachinery.com

- +0086-371-67991755