- Position:

- Batte Melt pump > NEWS >

What is the function of installing a metering melt pump on a small extruder in the laboratory?

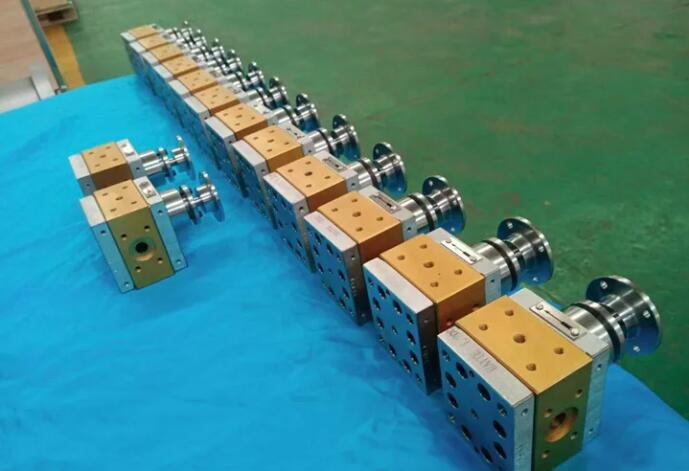

An indispensable part of a small extruder with precision extrusion is a melt metering pump, a device that accurately measures flow rate, which can measure the capacity of polymers and increase fluid pressure.

The main role of melt pump for extrusion in laboratory small-scale extrusion systems is:

1. Accurate measurement control;

2. Reduce the impact of screw oscillation;

3. Convey uniformly melted resin to the mold head;

4. Avoid uneven melting density;

5. Improve product quality;

6. Smaller product tolerances;

7. Save on raw materials.

The role of a melt metering pump in extrusion stability is self-evident. In the laboratory stage, after configuring a small extruder with a melt metering pump, it can approach the actual production environment to a large extent and prepare sample samples well, which has a very positive role in guiding the production process.

Email: info@battemachinery.com

Whatsapp: +86 158 38331071

Any questions about our products, please feel free to contact us! We promise you high-end products and first-class service.Look forward to our cooperation!!!

- sales@battemachinery.com

- +0086-371-67991755