- Position:

- Batte Melt pump > NEWS >

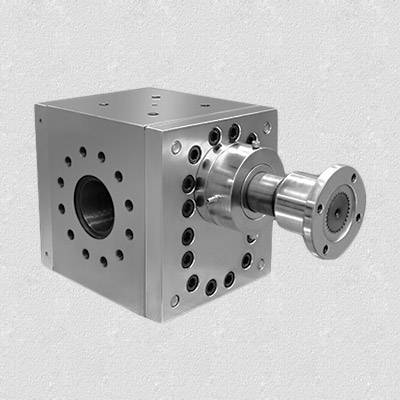

Why is a plastic extrusion line equipped with a melt pump?

The basic design of the melt pump determines that the dimensional error of the product can be well controlled at the time, especially in the profile extrusion process, because the specification control is extremely important, which is very important for the quality of the final product. By reducing the pressure fluctuation and giving a more stable die pressure, the melt pump can draw the dimensional error of the extruded product very well (usually plus or minus 5%). Can significantly increase product output and save materials, which is the first major benefit of installing a melt pump.

The basic design of the melt pump determines that the dimensional error of the product can be well controlled at the time, especially in the profile extrusion process, because the specification control is extremely important, which is very important for the quality of the final product. By reducing the pressure fluctuation and giving a more stable die pressure, the melt pump can draw the dimensional error of the extruded product very well (usually plus or minus 5%). Can significantly increase product output and save materials, which is the first major benefit of installing a melt pump.

In the actual production and application of the melt pump, other benefits of the melt pump include the ability to reduce energy consumption, reduce the abrasion of the extruder screw and barrel, and effectively improve the appearance of the final product, which is beneficial to sales.

Any questions about our products, please feel free to contact us! We promise you high-end products and first-class service.Look forward to our cooperation!!!

- sales@battemachinery.com

- +0086-371-67991755