- Position:

- Batte Melt pump > NEWS >

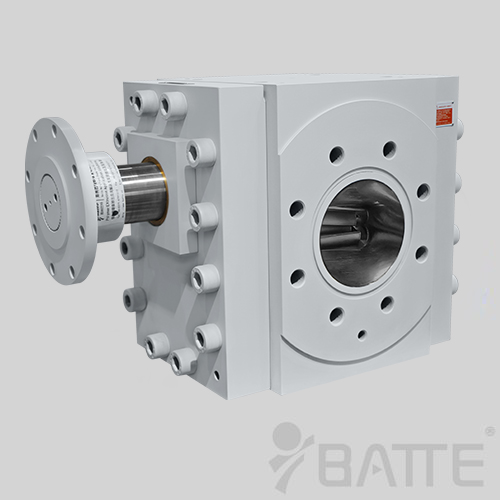

The use of polymer extrusion melt pump benefits

Polymer extrusion melt pump using the benefits as follows:

Improved dimensional stability ---- effectively isolated from the upstream mold and volatility.

Control of Melting mass ---- control back pressure regulator to reduce the extruder residence time, stability mastication effect and lower the melting temperature.

Increase production ---- Whether to increase production to establish the amount of pressure required, provide very high efficiency

Reduce the use of raw materials ----- Finished size of the final product to provide a small change

Fluctuations and the impact of the elimination of the screw ----- Effectively solve the problem because the density or melt extruder parameters caused

Enhanced flexibility of the extruder ----- Allowed to change the workpiece, such as: higher regrind usage, temperature and pressure.

Coronal tooth design ----- Reducing the internal shear forces of the Melt Pump for Extruder

Reasonable operating and functioning ---- Closed-loop control, PLC or smart meters

Extruder extend the life ---- Reducing the intensity of the work of the extruder, for example: pressure and torque.

Less operating costs---- Provide a more accurate measurement of the delivery, to avoid wasting raw material.

Any questions about our products, please feel free to contact us! We promise you high-end products and first-class service.Look forward to our cooperation!!!

- sales@battemachinery.com

- +0086-371-67991755