- Position:

- Batte Melt pump > NEWS >

Precision gear pump--the best support for improve the optimization of the production line

Automatic stop switch and a gear pump and the operation of the extruder

Starting and stopping the configuration parameters

Limit monitoring, production specifications configuration

Data transfer to the higher integration of the production line, such as the control system

Gear pump control system :

Gear pump control system to achieve a human-machine operation, can effectively regulate the melt pump production line to achieve optimal production.

Process advantages :

Eliminates pressure fluctuations, improved product quality to optimize product performance and enhance the products of the indicators save raw materials and reduce waste

Improved blending ( granulation ) in the production of particle size, uniformity of mass production to reduce energy consumption increases

Extrusion production line to provide optimal support to achieve no impact to switch between manual mode and automatic control mode

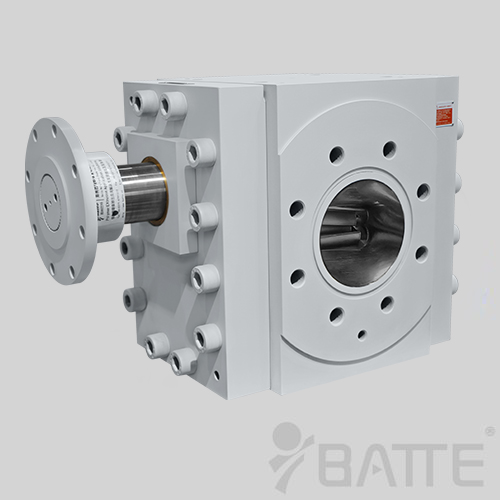

To create a stable and precise gear pump has been the study and research of sincere direction because high-precision gear pump extrusion of an essential part of the production line, and a certain degree of stability for the performance of the extruder to play to produce qualified quality products play a decisive role.

Gear pumps provide the required system pressure die to enhance and improve the efficiency and stability of extruded plastic materials, thereby increasing the efficiency of production lines, creating the best end product. After installing the gear pump, the maximum pressure in the extruder after the pump, which can decrease the pressure inside the extrusion line, the melt shear strength is lowered, flat temperature curve, the temperature rise is reduced. Fluctuations in pressure before the pump from the melt instability also played a role in an effective buffer, so that the peak pressure and pulse can be smooth or even completely eliminated, the pressure to create a stable production environment.

Gear pump core components - gears, is an effective measure to protect and pressurized, sincere mold is equipped with a gear pump wear breakthrough study the subtle changes between gears, rotating gears, self-lubricating bearings regulator introduced in Switzerland Seiko technology into product development, which provides a more stable and long-lasting protection for extrusion production lines.

After years of operation of the extruder, is generated between the internal screw and barrel wear greatly, resulting in the gap is too large, the return amount of the melt will increase, and the yield will be reduced and therefore the impact in increased after gear pump extrusion line, back flow and reduce energy loss, which means that the maximum increase production per unit time in the extruder, it is worth mentioning that each boot extruder, there are discharge machine longer period of time, which is the cost of production is a big waste, especially with some of the products the company in a short time to refueling or using masterbatch production, requiring multiple switch, in other words, with the use of a gear pump, in terms of the development of enterprises to play a role in the obvious cost reduction.

Material flow path, even a slight glitch will lead to blockage of the melt, thus affecting the quality of products, Goody from the gear pump inlet and outlet of the flow channel to achieve a comprehensive optimization design to ensure that the material handling very mild, Goody minor concern, and excellent treatment program showed that: sincerely committed to providing customers with the best gear pump.

Any questions about our products, please feel free to contact us! We promise you high-end products and first-class service.Look forward to our cooperation!!!

- sales@battemachinery.com

- +0086-371-67991755