- Position:

- Batte Melt pump > NEWS >

Batte Melt Pump in WPC production line

Batte Melt Pump in WPC production line

Melt pump is mainly used in high temperature and high viscosity of the polymer melt conveying, pressurization , and Measurement. Its main function is to melt from the extruder temperature pressurized regulator to maintain accurate and stable melt flow into the extrusion die . Today, melt gear pump has been widely used in chemical , grain , plastic film, sheet, plate , extrusions, pipes, wire and cable , wire drawing , composite extrusion production line , the material can be processed almost covers most polymer materials, such as : PE, PC, PP, PVC, HIPS, PS, PA, TPUR, fluoropolymers, polysulfones, polyesters, thermoplastic elastomer, rubber adhesives and hot .

WPC profile production line is mainly used for PVC + wood flour , production kick moldings , door line , Door Line , 100 leaves , photo frames , picture frames , door frames, Door, window cover , stand in vain , stair railings , decorative wall panel, furniture timber such as profile extrusion . WPC production line using unique technology and formula , according to different profiles section , different purposes, different proportion of product design , the choice of different specifications of WPC special twin-screw extruder , with Batte special melt pump . Tractor uses a unique technology , steady work , good reliability, great traction .

Increased use of special vacuum stereotypes swirl cooling system, to facilitate cooling stereotypes , WPC profile production to meet the needs of the characteristics . Cutting speed traction devices and profiles to keep pace , reasonable design , stable operation can be automatically cut to length and equipped with dust recovery .

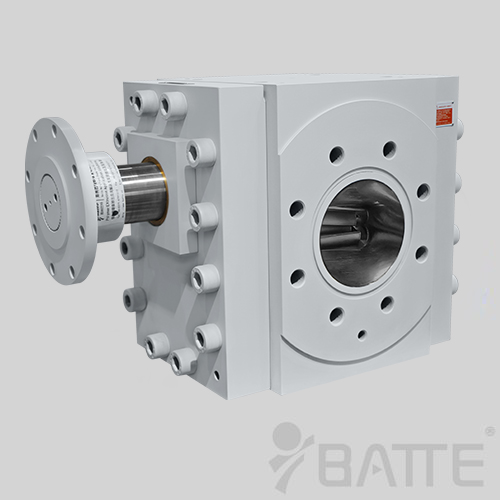

Batte melt pump is a positive displacement transportation equipment, precision gear clearance and volume structure designed to make it possible stable equilibrium extrusion , chemical fiber , granulation, plastic film, sheet, plate , extrusions , pipes, wire and cable , wire drawing , composite extrusion production line is widely used , and achieved good results :

1 Use melt gear pump feeding system eliminates feeding errors can be greatly reduced fluctuations upstream process passed quickly into the stable working conditions, improve the dimensional accuracy of extruded products , reduce scrap rates.

2 to increase production , reduce energy consumption, low temperature extrusion, longer machine life. Since the installation of the extruder the polymer melt pump , the pressure is transferred to the function of the extruder gear pump is completed , the extruder can be operated at low temperature and pressure state , the leakage flow is greatly reduced, the yield is improved.

3 has a linear extrusion characteristics , easy on the downstream device coordination. As the gear pump leakage is less traffic , transport capacity and speed of the pump basically a linear relationship , the gear pump speed changes , the flow can know exactly , because you can determine the downstream equipment and gear pump operating speed sync , use a gear pump inlet pressure at the outlet collection , temperature and other information , the entire extrusion process throughout the on-line monitoring and feedback control.

Any questions about our products, please feel free to contact us! We promise you high-end products and first-class service.Look forward to our cooperation!!!

- sales@battemachinery.com

- +0086-371-67991755