- Position:

- Batte Melt pump > technic >

Production process of melt blown cloth

1. Polymer feed. The polymer is generally made into small spherical and granular slices, which are poured into the barrel or hopper and fed into the screw extruder.

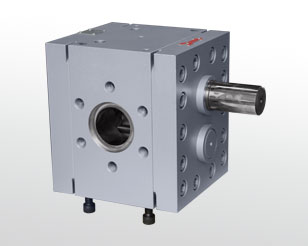

2. Melt extrusion. At the feed end of the screw extruder, the polymer chips, additives and other necessary raw materials are fully stirred and mixed into the screw extruder, heated to melt, and finally sent to the spinneret by the metering pump through the filter. In the melt blown process, the molecular weight of polymer is reduced by the shear and thermal degradation of extruder.

3. Fiber formation. The clean melt filtered by the screen changing filter shall pass through the distribution system, and then be evenly fed into each group of spinnerets, so that the extrusion amount of each spinneret hole is the same (is it very similar to the multi cavity hot runner of injection molding?). The spinneret of melt blown fiber is different from other spinning methods. The spinneret holes must be arranged in a straight line with high-speed air jet holes on both sides.

Any questions about our products, please feel free to contact us! We promise you high-end products and first-class service.Look forward to our cooperation!!!

- sales@battemachinery.com

- +0086-371-67991755