- Position:

- Batte Melt pump > NEWS >

Thermosensitive PVC Melt Gear Pump for Extrusion

In the field of plastics processing, PVC (polyvinyl chloride) is widely used in the production of pipes, sheets, films, and other products due to its excellent properties. However, PVC's thermosensitive nature results in a narrow processing window, making it highly sensitive to temperature fluctuations. Localized overheating can easily cause decomposition, carbonization, or even the formation of scorch, severely impacting product quality and production line continuity.

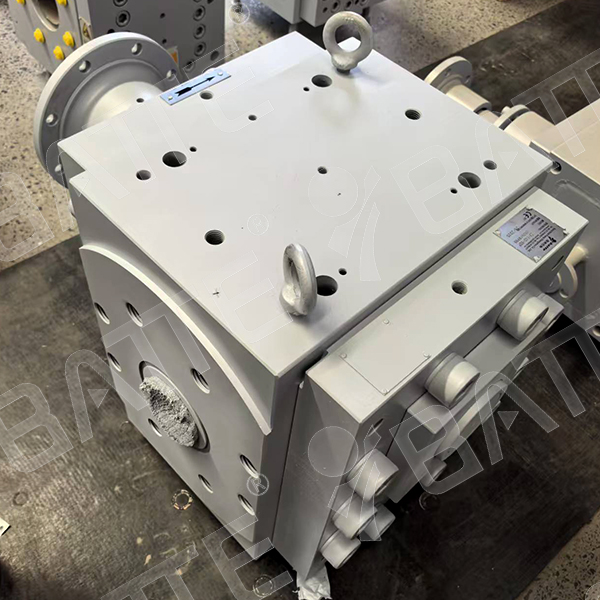

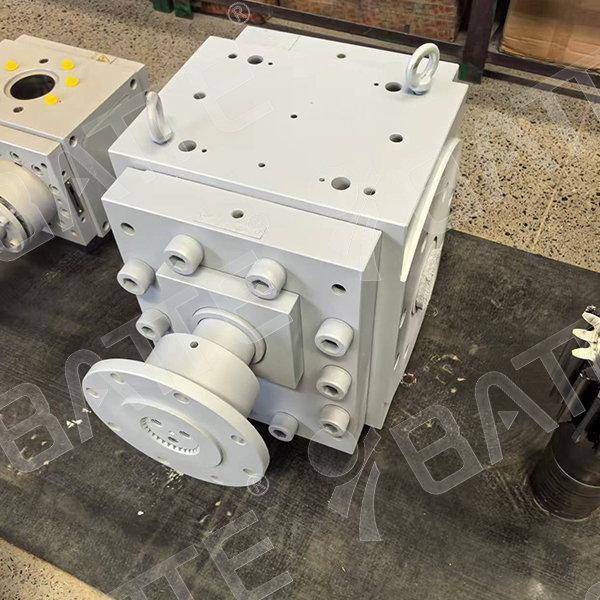

Addressing this industry challenge, Batte Machinery leverages its deep understanding of material properties and extensive technical expertise to introduce a specialized PVC melt gear pump solution. The ZB-C series melt pump stands as a proven, reliable choice validated through extensive practical application.

I. Core Challenges in PVC Material Processing

As a non-crystalline, thermosensitive polymer, PVC's processing challenges primarily stem from:

Poor thermal stability: Under high temperatures or prolonged heating, it readily undergoes dehydrochlorination reactions, leading to chain breakage, discoloration, and performance degradation.

High melt viscosity and shear sensitivity: Processing requires precise balancing of temperature and shear force; otherwise, melt fracture or degradation may occur.

Extremely Demanding Process Control: Minor temperature or pressure fluctuations can be amplified, causing unstable outlet flow and resulting in product defects such as uneven thickness and surface imperfections in sheets, pipes, and profiles.

Traditional methods relying solely on screw extruders to generate pressure often involve significant temperature and pressure pulsations, making it difficult to meet the precision extrusion requirements for PVC.

II. PVC Melt Pump Core Solution

Batte Machinery's solution centers on separating the “pressure build-up” and “metering” functions from the screw extruder through positive displacement conveyance equipment—the melt gear pump. This achieves revolutionary optimization of PVC melt conveyance.

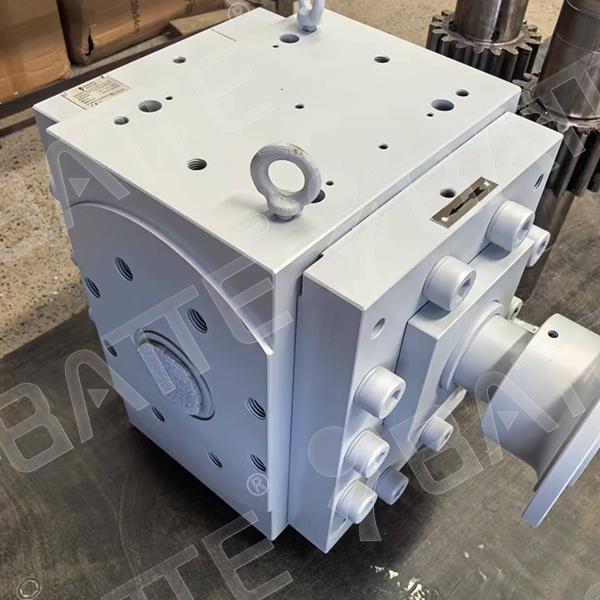

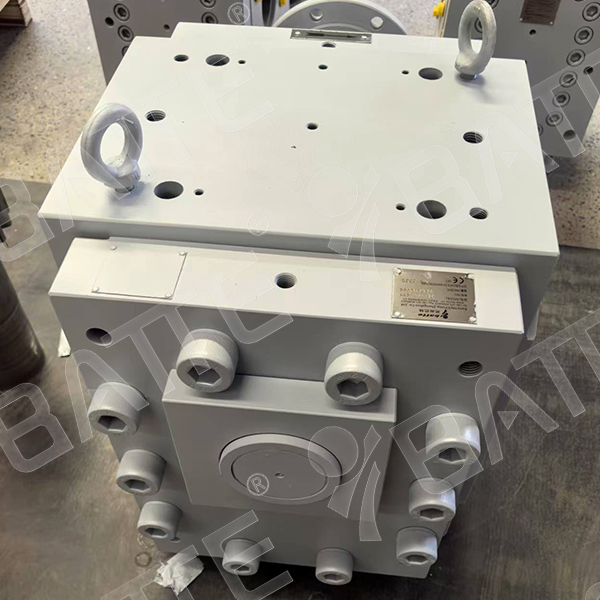

Represented by the ZB-C series gear pumps, these PVC melt pumps feature comprehensive adaptive designs tailored to material properties:

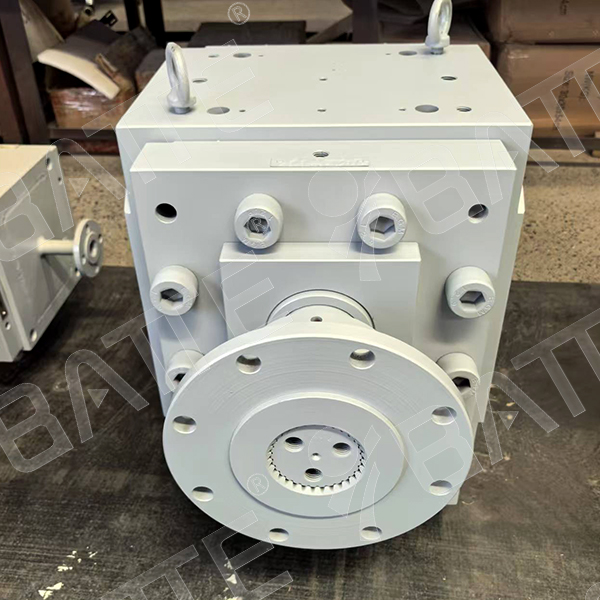

Optimized flow channels and gear design: The inlet employs a bell-shaped flow channel, ensuring PVC melt enters the meshing zone smoothly and stably while minimizing shear-induced heat generation and flow dead zones. Internal flow paths and gear parameters are specially optimized for low pressure loss and highly uniform conveying.

Built-in Melt Self-Lubrication System: A unique lubrication channel design enables a small amount of melt to self-lubricate critical components like gear shaft sleeves. The lubricant is discharged alongside the main material, eliminating the need for external oil lines. This simplifies the structure and prevents contamination of PVC material by external lubricants, making it particularly suitable for PVC product manufacturing scenarios with high cleanliness requirements.

High-precision gear clearance and volumetric structure: Through strict control of gear clearance and volumetric cavity design, the melt pump precisely regulates material delivery volume. This eliminates extrusion instability caused by upstream processes like uneven feeding or temperature fluctuations, enabling high-precision continuous extrusion.

ZB-C Series Melt Gear Pump Key Technical Parameters

Conveyed Medium Viscosity: 1~40000 Pa·s Suction Pressure: 0~30 MPa

Discharge Pressure: 0~40 MPa

Allowable Pressure Differential: 25 MPa

Operating Temperature: ≤350℃

Heating Method: Electric Heating/Thermal Fluid Channel Heating

Significant Benefits of Batte Melt Pumps for PVC Processing

Installing Wuhua melt pumps on extrusion production lines for PVC sheets, plates, pipes, profiles, and wire/cable jackets has proven to deliver multiple significant improvements:

1. Achieves ultra-stable extrusion, substantially enhancing product precision:

The melt pump functions as a “pressure stabilizer,” completely eliminating output fluctuations caused by feed variations, screw pulsation, and temperature changes in the upstream extruder. It supplies constant, pulsation-free melt pressure and flow to the downstream die, enabling more precise dimensional tolerance control of PVC products, greatly improving thickness uniformity, and significantly reducing scrap rates.

2. Increased output and reduced overall energy consumption:

After installing a melt pump, the extruder handles only plasticizing and compounding functions, while pressure build-up is performed by the more efficient gear pump. This allows the extruder to operate at lower back pressure and temperature, reducing screw leakage flow and axial load. Overall system energy consumption can decrease by 10%-25%, while extruder output increases by up to 30%. It also effectively extends the service life of the screw and gearbox.

3. Leveraging Linear Output Characteristics for Intelligent Control:

The output flow rate of gear pumps exhibits a strictly linear relationship with rotational speed. This characteristic simplifies and enhances the precision of production line control. By monitoring inlet/outlet pressure and temperature of the pump and coordinating with equipment such as extruders and haul-offs, seamless automation and intelligent coordination across the entire production line can be achieved, ensuring exceptional process repeatability.

Batte offers complete solutions ranging from single pumps to integrated systems including drives, control systems, and screen changers, ensuring seamless compatibility and efficient operation with existing production lines. Choosing Bartec means partnering with a company that deeply understands PVC processing technology, delivers reliable equipment, and provides ongoing technical support.

Email: sale@meltpump.com

WhatsApp: +86 158 3833 1071

Any questions about our products, please feel free to contact us! We promise you high-end products and first-class service.Look forward to our cooperation!!!

- sales@battemachinery.com

- +0086-371-67991755