- Position:

- Batte Melt pump > NEWS >

Melt Pumps and Screen Changers for PP Modified Granulation Production Lines

In PP modified granulation production lines, melt pumps and screen changers serve as core auxiliary equipment ensuring product quality and process stability. Their coordinated operation resolves critical issues such as fluctuations in PP melt delivery and incomplete impurity filtration.

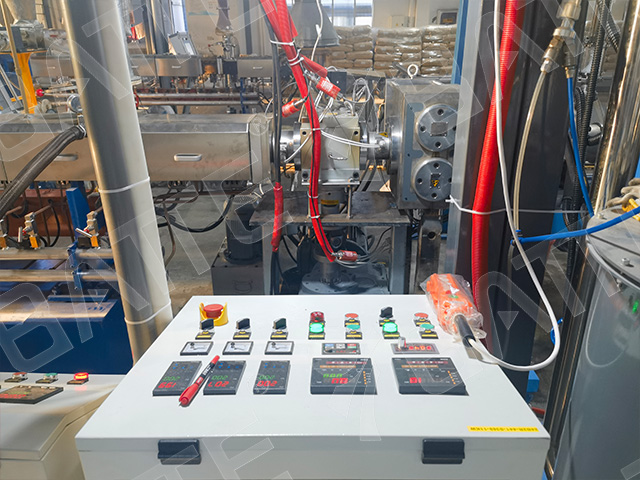

Melt Pump: Precisely meters and delivers melt at constant pressure, converting unstable extruder discharge into steady flow output.

Key Value: 1. Eliminates extrusion fluctuations caused by temperature/pressure variations in PP melt, ensuring uniform pellet size;

2. Reduces extruder load, enhances screw plasticizing efficiency, and minimizes PP degradation risk.

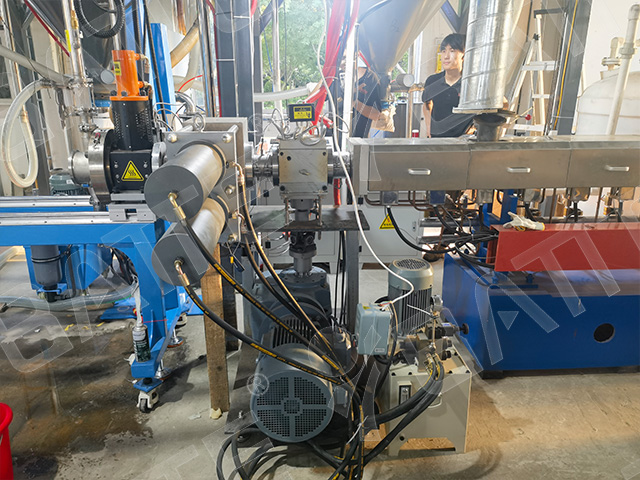

Screen Changer: Online filtration of melt impurities (e.g., glass fiber fragments, carbon black agglomerates, equipment wear debris).

Key Value: 1. Prevents impurities from scratching die heads or clogging pelletizers, ensuring continuous pelletization;

2. Enhances cleanliness of modified PP pellets to meet high-end applications (e.g., automotive components, appliance housings).

1. Key Parameters for Melt Pump Selection

Modified PP materials (e.g., glass-fiber reinforced PP, mineral-filled PP) exhibit high melt viscosity and strong abrasiveness. Selection must prioritize:

Pump Body Material: Select nitrided steel (38CrMoAlA) or duplex stainless steel to resist glass fiber/mineral wear and prevent metal particle contamination of the melt;

Flow Matching: Select melt pumps with corresponding displacement based on pelletizing line capacity (e.g., 500kg/h, 1000kg/h). Gear-type melt pumps are recommended (metering accuracy ±1%, suited to PP melt characteristics).

Sealing System: Employ double-ended mechanical seals + nitrogen protection to prevent high-temperature oxidation of PP melt and avoid material leakage.

Temperature Control Accuracy: Pump body temperature control error ≤ ±1°C to prevent PP melt degradation and yellowing caused by localized overheating.

2. Key Parameters for Screen Changer Selection

PP modified pelletization requires frequent impurity filtration. Prioritize non-stop screen changers (to avoid production loss from shutdowns). Specific selection:

Filter Type:Glass-fiber reinforced PP: Recommend plate-type dual-station screen changers (large filtration area, high contaminant capacity, suitable for filtering glass fiber fragments);

Highly filled PP (e.g., talc-filled): Select cartridge-type screen changers (superior sealing performance prevents fine powder leakage);

Mesh Specifications:

Select based on modified PP product requirements. Standard choice: 80-120 mesh stainless steel mesh.

For premium products, add a 150 mesh filter for finer filtration.

Abrasion-Resistant Design:

Mesh support components use hard alloy materials to resist wear from fillers and extend service life.

Drive method: Hydraulic drive (enables rapid screen changes with minimal pressure fluctuations, preventing melt pressure surges during screen changes that cause particle size variations).

Email: sale@meltpump.com

WhatsApp: +86 158 3833 1071

Any questions about our products, please feel free to contact us! We promise you high-end products and first-class service.Look forward to our cooperation!!!

- sales@battemachinery.com

- +0086-371-67991755