- Position:

- Batte Melt pump > NEWS >

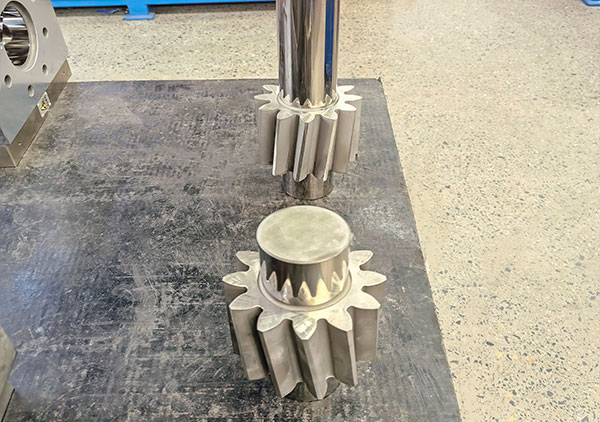

Material Selection for Melt Pump Gears

The selection of melt pump gear material hinges on the application scenario and required performance. A variety of materials are available for melt pump gears.

First, nitrided steel offers excellent wear resistance, making it suitable for high-pressure and high-wear applications. Tool steel provides both high hardness and wear resistance, ideal for high-strength gears. Stainless steel exhibits strong corrosion resistance, suitable for corrosive media. Corrosion-resistant alloys like Hastelloy are appropriate for extreme corrosion environments. Special alloys such as titanium alloys are well-suited for high-temperature and high-pressure conditions.

Additionally, coating materials like tungsten carbide or ceramic coatings can enhance wear and corrosion resistance. Beyond physical and chemical properties, selection should also consider cost, machinability, material availability, and ease of maintenance and replacement. Choosing the appropriate material for melt pump gears ensures stable pump operation and extended service life. It is essential to make decisions based on comprehensive evaluation of actual requirements.

In summary, the selection of melt pump gear materials must be based on application scenarios and performance requirements. Options include nitrided steel, tool steel, stainless steel, corrosion-resistant alloys, special alloys, and coated materials. A comprehensive evaluation of physical and chemical properties, cost, machinability, material availability, and maintenance convenience is essential to ensure stable pump operation and extended service life.

Email: sale@meltpump.com

WhatsApp: +86 158 3833 1071

Any questions about our products, please feel free to contact us! We promise you high-end products and first-class service.Look forward to our cooperation!!!

- sales@battemachinery.com

- +0086-371-67991755