- Position:

- Batte Melt pump > NEWS >

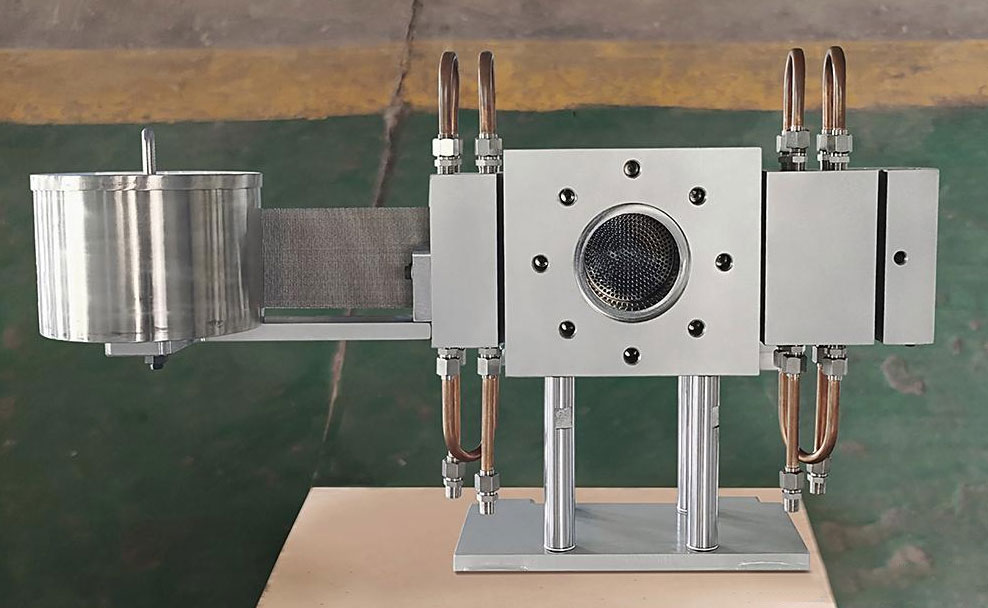

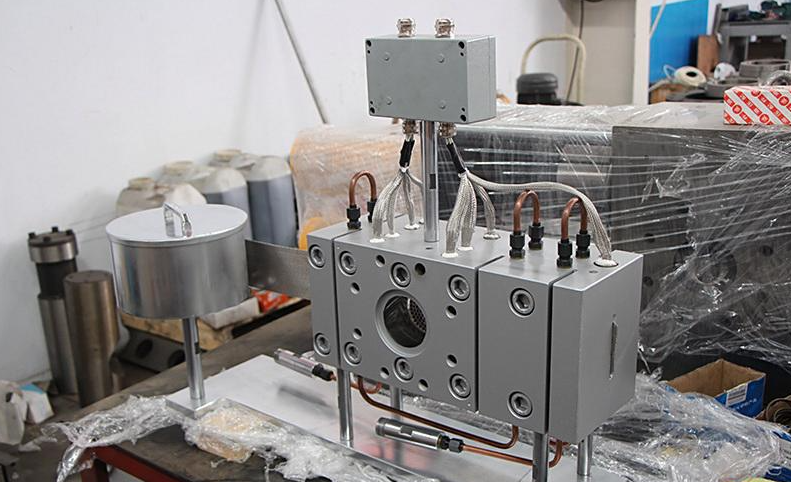

Core Components of the Mesh Belt Automatic Screen Changer

Mesh Belt with Contrasting Patterns

As the core filtration element, it is crafted from specialized materials that combine high strength with temperature resistance. Its fine mesh removes impurities from the melt.

Filter Screen Housing

Secures and protects the mesh belt, preventing melt leakage while facilitating maintenance and replacement.

Inlet Cooling Section

Reduces melt temperature via cooling pipes, preventing viscosity changes or equipment damage caused by high heat.

Main Flow Channel Connection Section

Links the inlet cooling section, filter screen housing, and outlet cooling section to form a sealed melt flow pathway.

Outlet Cooling Section

Provides secondary cooling to the filtered melt, ensuring temperatures meet subsequent process requirements.

Heating Elements

Heat the melt during screen changes to facilitate smooth screen movement and impurity removal.

Electrical Control System

Monitors melt pressure in real time or triggers screen movement based on time intervals, enabling automated control.

Email: sale@meltpump.com

WhatsApp: +86 158 3833 1071

Any questions about our products, please feel free to contact us! We promise you high-end products and first-class service.Look forward to our cooperation!!!

- sales@battemachinery.com

- +0086-371-67991755