- Position:

- Batte Melt pump > NEWS >

Polymer melt pump installation steps

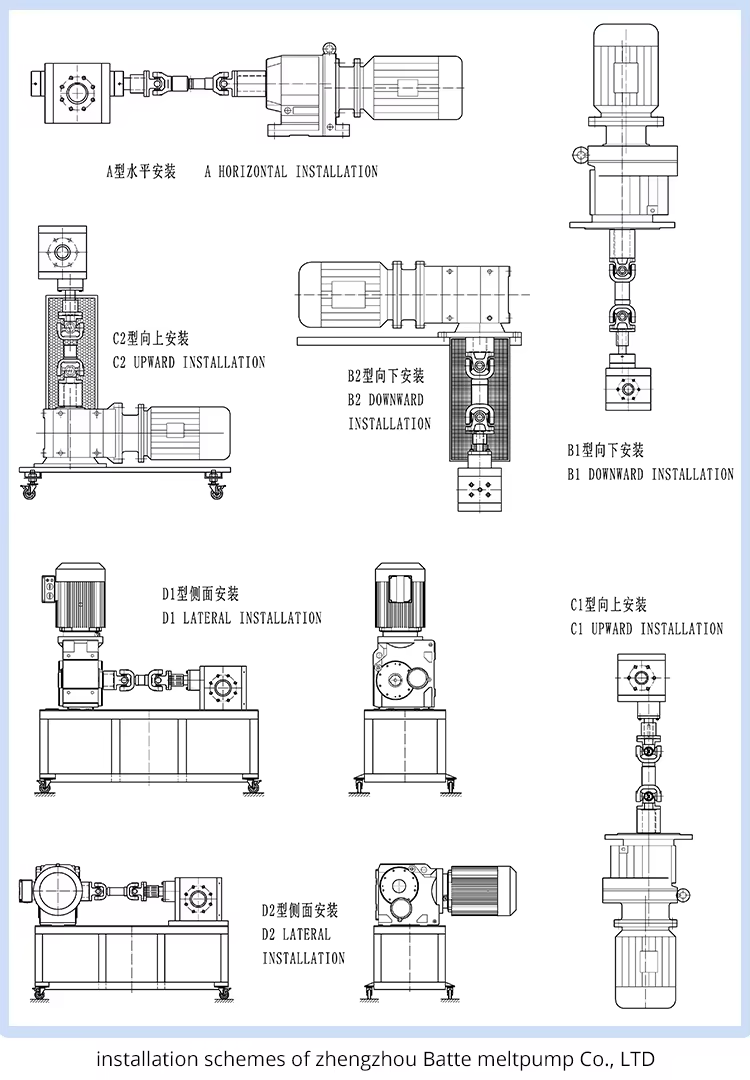

Preparation Before Installing the Melt Pump Before installing the melt pump, a series of preparatory steps must be completed. First, ensure the installation site is clean, dry, and well-ventilated. Simultaneously, verify that the foundation for the melt pump is level and secure to prevent vibration or displacement during equipment operation.

Foundation Installation:

1. Position the foundation at the designated location according to the design drawings and adjust its level. Ensure the contact surface between the foundation and the ground is free of debris, and that sufficient space surrounds the foundation for subsequent installation work.

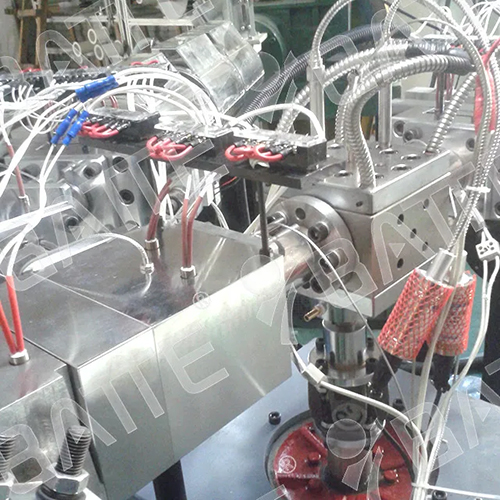

2. Pump Housing Installation: Position the melt pump housing on the foundation. Adjust its position and height to ensure the pump shaft is level. Secure the housing to the foundation with bolts, ensuring all connections are tight and leak-free.

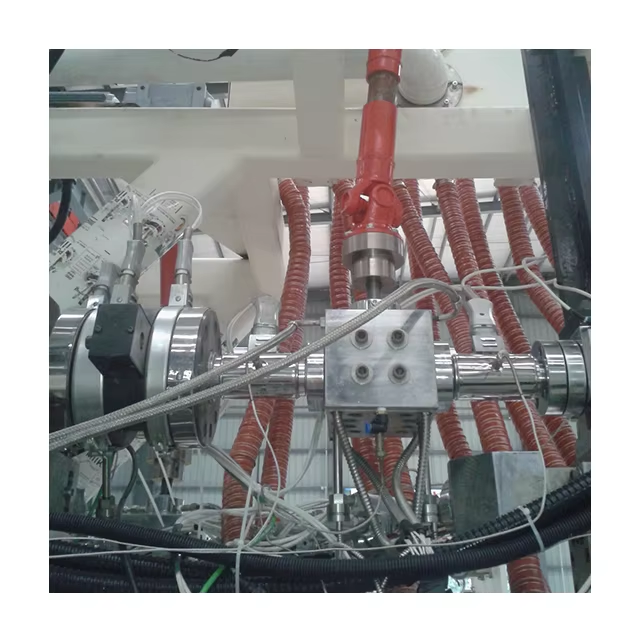

3. Motor Installation: Position the motor in its designated location and connect it to the pump housing. Ensure the motor and pump housing centerlines are aligned, and the motor base is firmly anchored to the foundation.

Seal Installation: Select appropriate seals according to equipment requirements and install them in the correct orientation onto the pump body and motor. Ensure seals are free from distortion or damage to prevent compromised sealing performance. 5. Pipeline Connection: Connect the transfer pipelines to the melt pump's inlet and outlet as required, ensuring all connections are tight and leak-free. Provide adequate support and secure the pipelines to prevent vibration or displacement.

Electrical Connection: Connect the motor, sensors, and other components of the melt pump to the control cabinet or electrical control system according to the electrical schematic. Ensure all connections are correct and secure to prevent electrical faults or safety hazards.

Commissioning and Trial Operation: After completing the above installation steps, commission and trial run the melt pump. Verify the correct rotation direction, assess sealing integrity, and confirm flow rate and pressure meet specifications. Address any issues promptly through adjustment or repair.

Precautions:

1. Strictly adhere to the equipment manual and operating procedures during installation to ensure quality and safety.

2. For high-precision, high-demand melt pumps, installation and commissioning should be performed by qualified personnel to guarantee equipment performance and accuracy.

Email: sale@meltpump.com

WhatsApp: +86 158 3833 1071

Any questions about our products, please feel free to contact us! We promise you high-end products and first-class service.Look forward to our cooperation!!!

- sales@battemachinery.com

- +0086-371-67991755